SOPHON provides efficient, eco-friendly, energy-saving, and flexible solutions for material conveyance in the new energy industry, which helps to promote the sustainable development and innovation of the industry.

SOPHON satisfies the special process requirements such as mixing, crushing, cooling and dust removal in the chemical industry. Some reaction intermediates sensitive to oxygen and water can be convey- ed with inert gas protection.

Material conveyance through fully-enclosed pipeline avoids dust and other foreign matter, thus ensuring the cleanliness of raw materials and product safety.

SOPHON provides precise and efficient material conveying systems in the plastic industry that can handle both raw material particles and finished plastics, ensuring the continuity of production process and product quality.

To meet the requirements of high cleanliness and sterility for material conveyance in the pharmaceutical industry, SOPHON adopts special materials and sealing design to effectively prevent cross-contamination and ensure the safety and effectiveness of drug production.

Considering the particularity of the new material industry, SOPHON provides customized material conveying solutions to handle special materials with high temperature, high viscosity and corrosion.

-

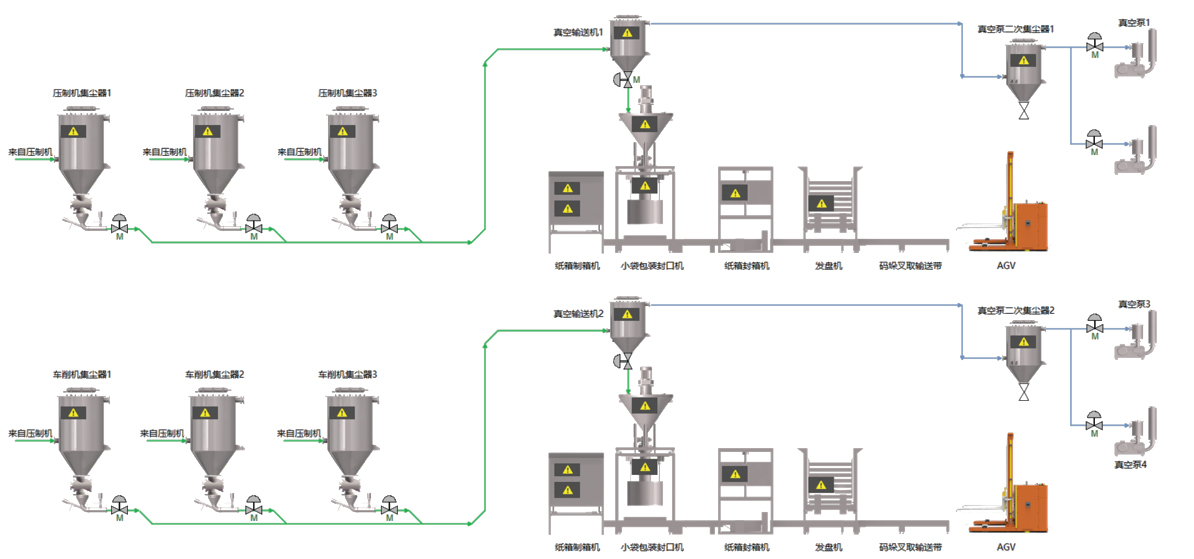

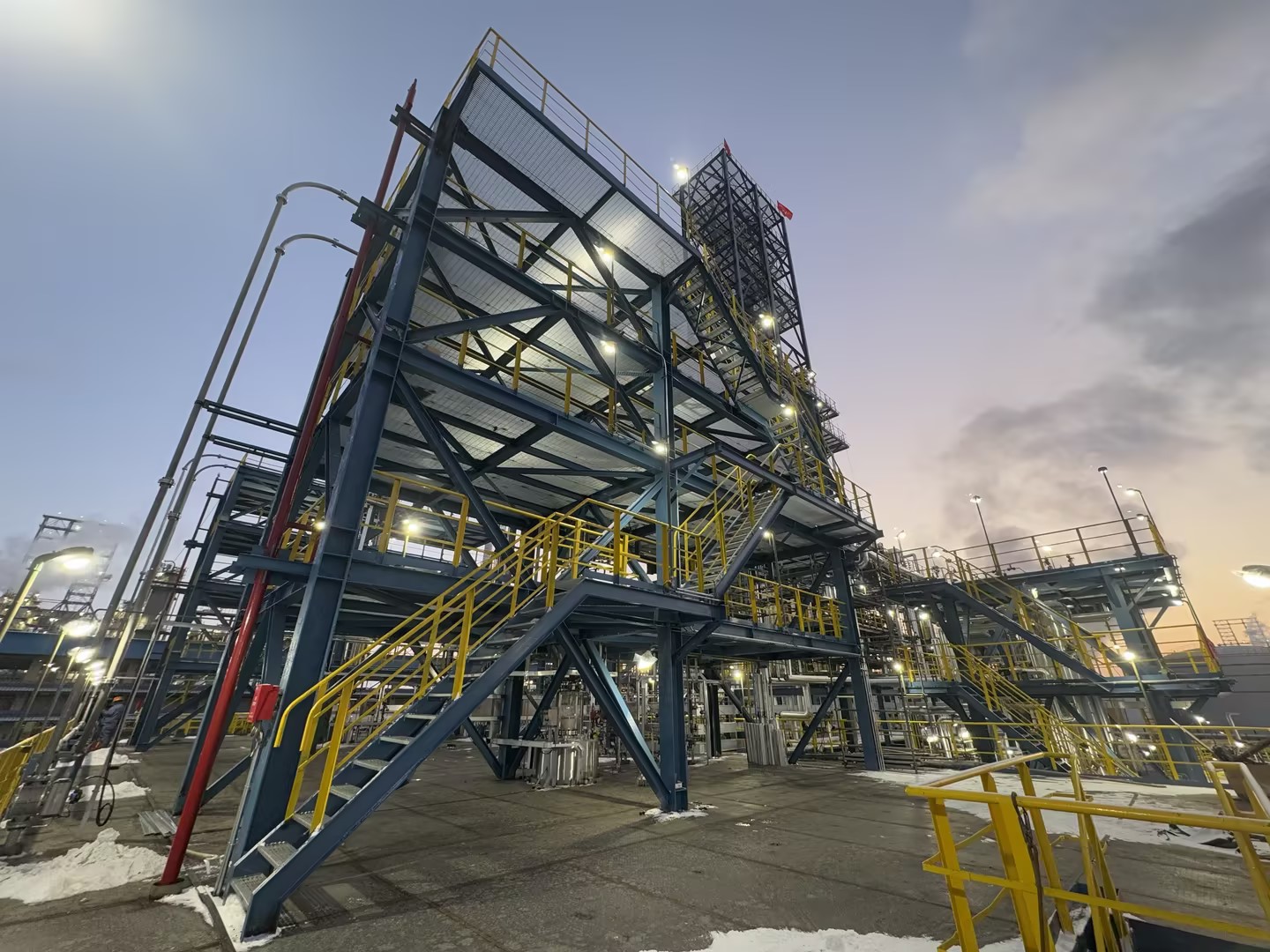

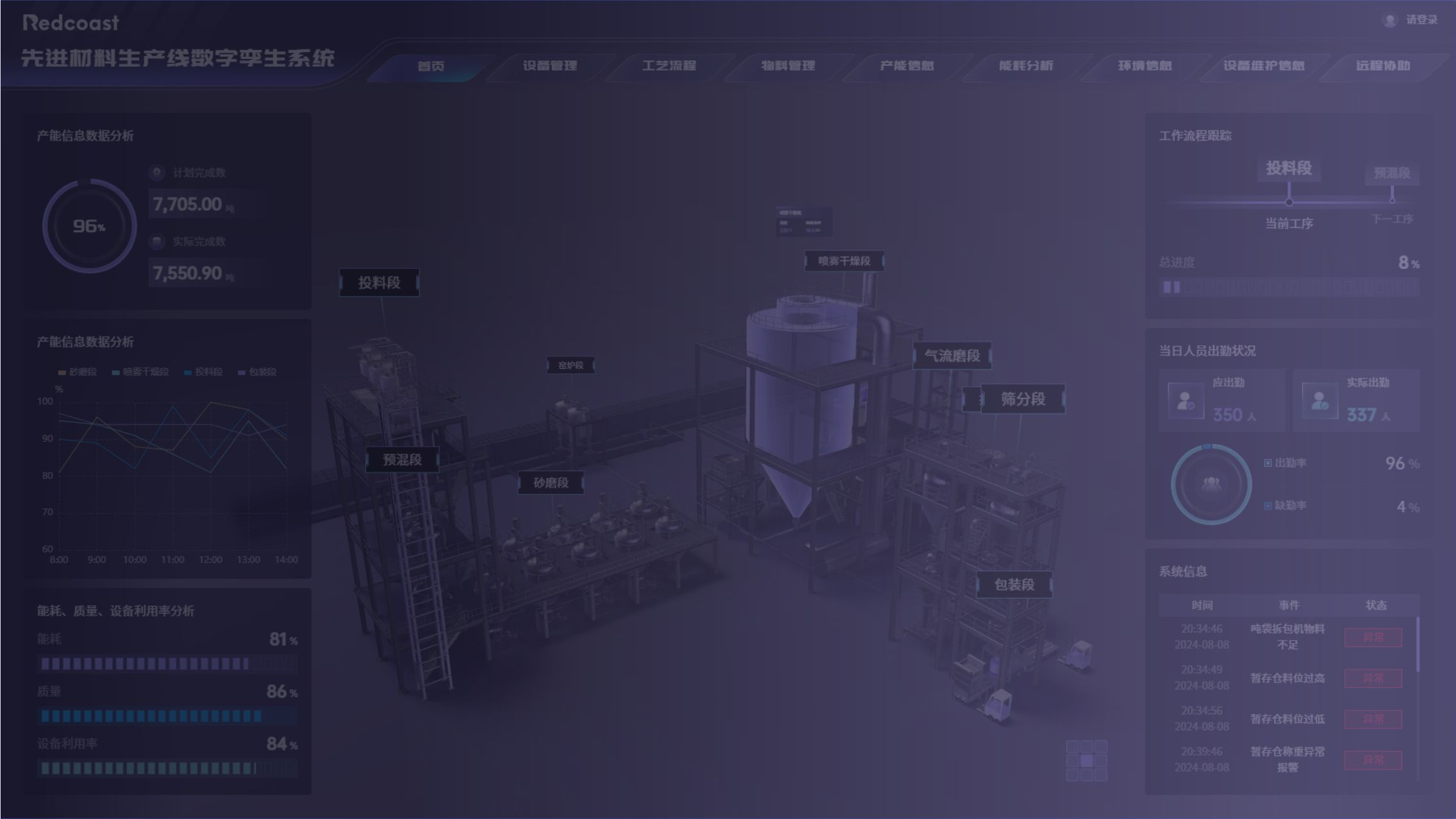

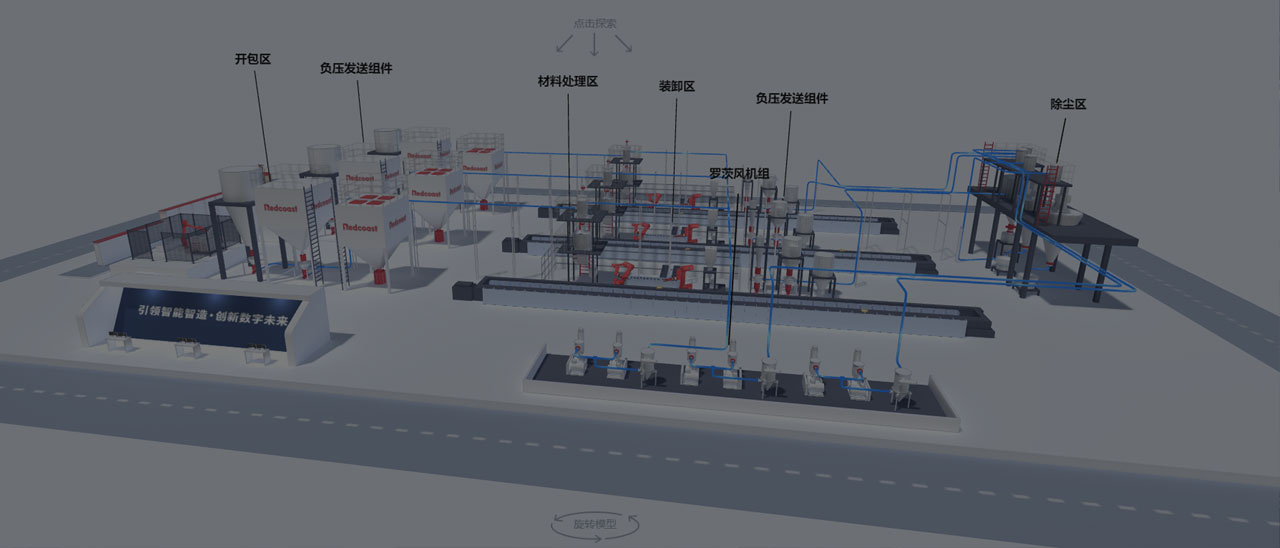

EPC Turnkey ServicesCommitted to becoming a world-leading service provider of material handling technologies (Digital production line design + Turnkey engineering)

EPC Turnkey ServicesCommitted to becoming a world-leading service provider of material handling technologies (Digital production line design + Turnkey engineering) -

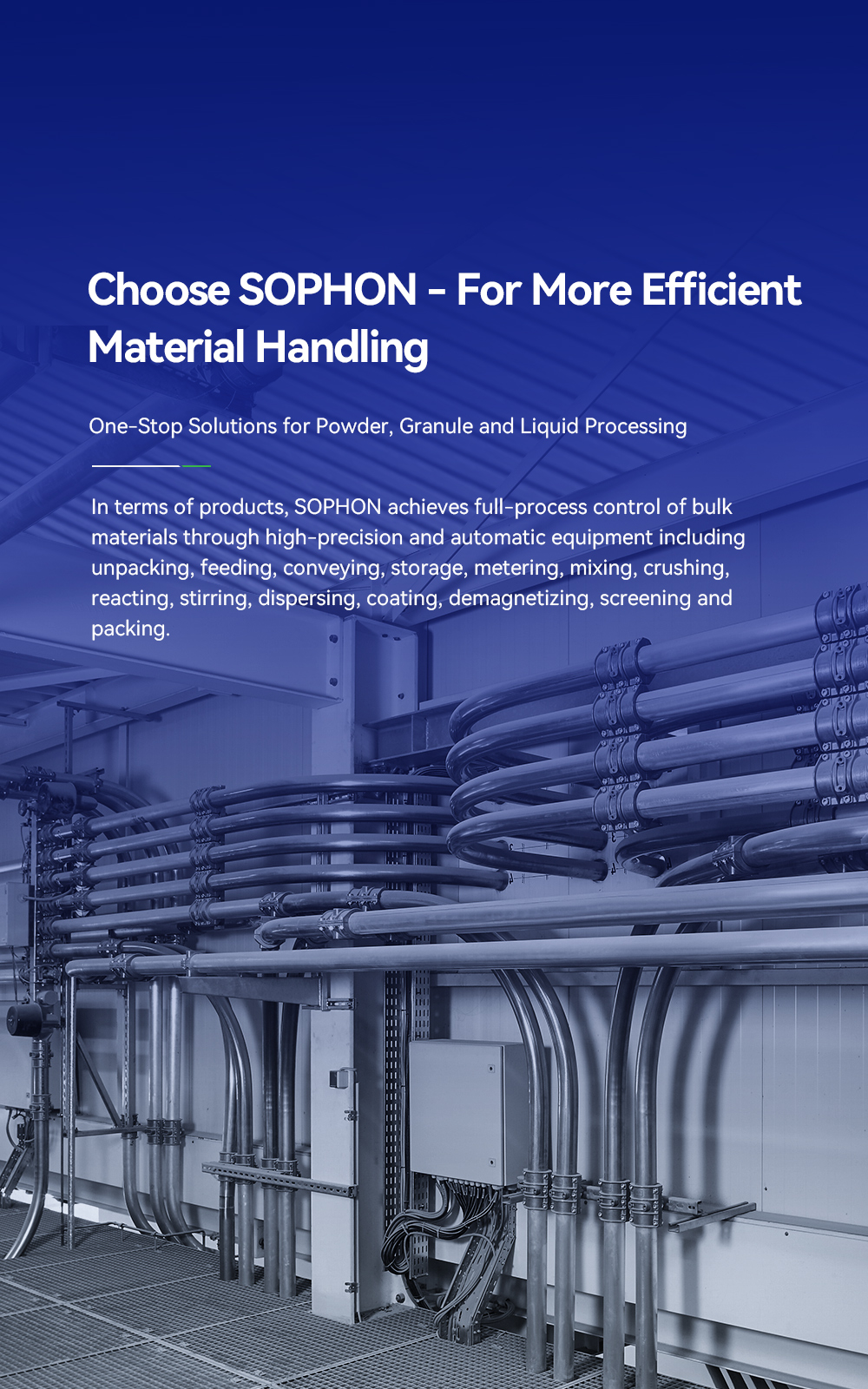

Pneumatic Conveying SystemPositive-pressure conveying/ Negative-pressure conveying/ Dense-phase conveying

Pneumatic Conveying SystemPositive-pressure conveying/ Negative-pressure conveying/ Dense-phase conveying -

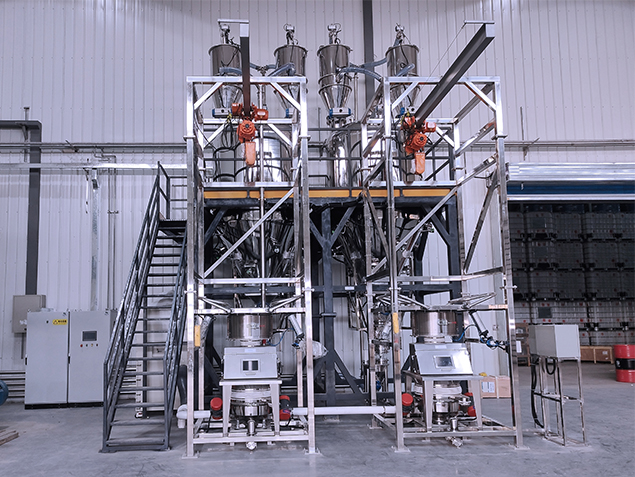

Centralized Feeding SystemFluid/ Powder/ Paste/ Particle/ Micro materials

Centralized Feeding SystemFluid/ Powder/ Paste/ Particle/ Micro materials

-

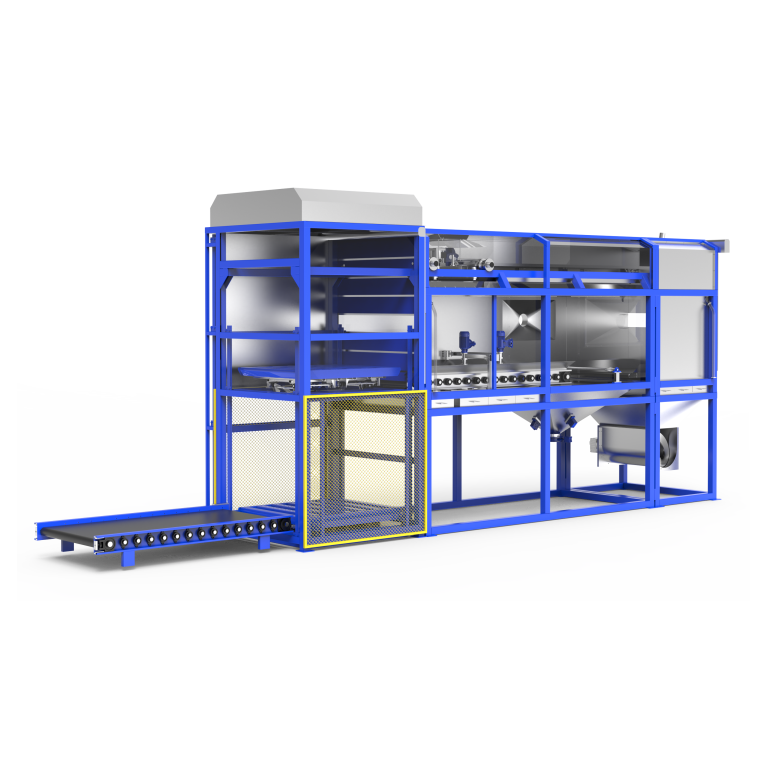

Fully-automatic Bulk Bag Unloader

Fully-automatic Bulk Bag UnloaderThe Fully-automatic Bulk Bag Unloader, specifically designed for the unpacking of bulk granular and powdered materials in industries such as chemical, new energy, minerals, and grain. lt effectively addresses issues associated with traditional manua unpacking, including low efficiency, heavy dust pollution, and significant material loss.

-

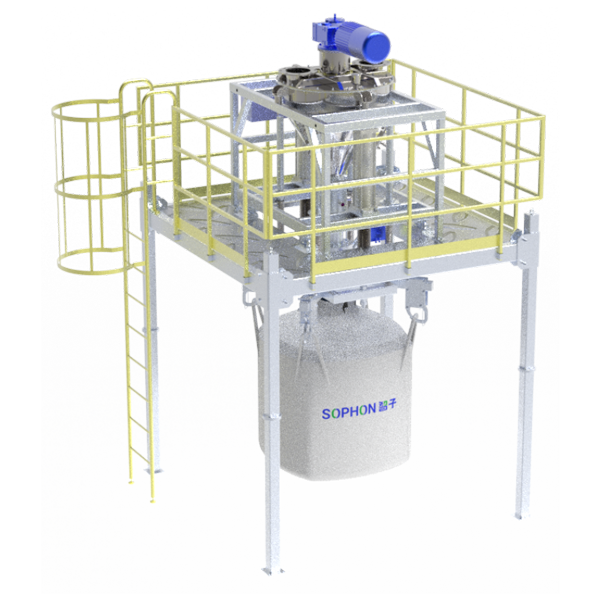

Vertical Bulk Bag Loader

Vertical Bulk Bag LoaderBy integrating automation technology, vacuum degassing system, and high-precision control, safe and efficient packaging of powder and granular materials is achieved.

-

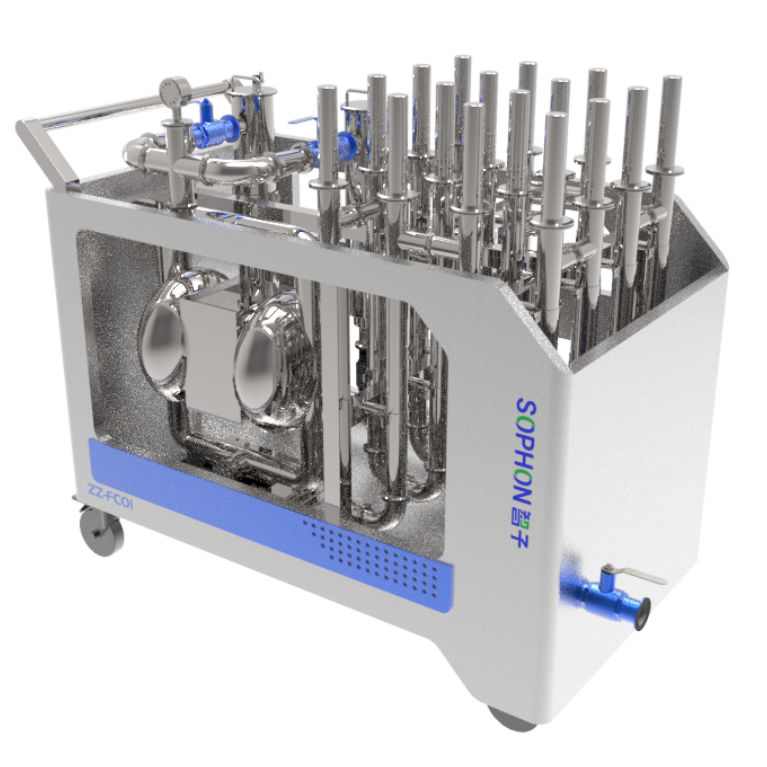

Iron Removal Filter Trolley

Iron Removal Filter TrolleyThe Iron Removal Filter Trolley is a portable iron removal device specially designed for extracting magnetic particles from fluid or semi-fluid materials.

-

High-efficiency Magnetic Separator

High-efficiency Magnetic SeparatorThe high-efficiency magnetic separator is a semi-automatic machine designed to remove iron impurities and other ferromagnetic particles from fluid or semi-fluid materials.

-

High-speed Disperser

High-speed DisperserThe High-speed Disperser, as a device specially designed for mixing, dispersing or emulsifying solid-liquid or liquid-liquid mixtures, has shown significant advantages in handling solid particles smaller than 10μm. Compared with traditional mixing and dispersing equipment (such as dual planetary mixers), high-speed dispersers have shown more outstanding performance and advantages with their unique multi-layer stator and rotor structure.

-

Positive Pressure Bin Pump

Positive Pressure Bin PumpDense Phase Tank-type Pneumatic Conveying Bin Pump, abbreviated as Bin Pump or Pneumatic Conveying Bin Pump, is a pneumatic conveying system specifically designed for highly abrasive powdered and granular materials. It integrates advanced material handling technology with intelligent control, achieving disruptive upgrades in energy consumption reduction, maintenance cost minimization and zero dust leakage.

-

Xiamen tungsten industry new energyProud of every sincere cooperation

Xiamen tungsten industry new energyProud of every sincere cooperation Fujian Metallurgical Industry Design InstituteProud of every sincere cooperation

Fujian Metallurgical Industry Design InstituteProud of every sincere cooperation Geely YiyuanProud of every sincere cooperation

Geely YiyuanProud of every sincere cooperation Bump cycle

Bump cycle Baijeri

Baijeri Hanrui cobalt industry

Hanrui cobalt industry Pengbo new Materials

Pengbo new Materials Xingfa Group

Xingfa Group Timesys

Timesys Five creative cycles

Five creative cycles Qujinglin iron technology

Qujinglin iron technology Jingmensleer

Jingmensleer Guanghua Technology

Guanghua Technology De Fang Yi Wei

De Fang Yi Wei -

-

Xinyi Energy

Xinyi Energy Hessian energy storage

Hessian energy storage Tiango Energy

Tiango Energy Camel Group

Camel Group Haopeng Technology

Haopeng Technology Xing Dong lithium electricity

Xing Dong lithium electricity Shaanxi coal industry

Shaanxi coal industry Yexiang Crystal

Yexiang Crystal GREPOW

GREPOW Therford Energy

Therford Energy Nind era

Nind era ATL New Energy

ATL New Energy TTI

TTI Hive energy

Hive energy Ripulanjun

Ripulanjun Floating energy technology

Floating energy technology Positive force new ability

Positive force new ability Vico

Vico Tianneng Stock

Tianneng Stock -

Protalite

Protalite Star source material

Star source material Guangdong Zhuogao

Guangdong Zhuogao Jinli Group

Jinli Group Cangzhou pearl

Cangzhou pearl Dezhou Donghong

Dezhou Donghong Zhongxing New Materials

Zhongxing New Materials Medium material lithium film

Medium material lithium film Kelanto

Kelanto Jiangyin sodium force

Jiangyin sodium force -

Lando biomaterials

Lando biomaterials Top Zhi food

Top Zhi food Gold elephant

Gold elephant Twinings organism

Twinings organism Kelun Pharmaceutical

Kelun Pharmaceutical -

Sinopec

Sinopec Wan Hua

Wan Hua Real Madrid

Real Madrid FEELM

FEELM Huizhou Anpin

Huizhou Anpin Dellian Group

Dellian Group Huazong Group

Huazong Group New bright chemistry

New bright chemistry Rivers

Rivers Sink energy

Sink energy Rongsheng Petrochemical Co., Ltd.

Rongsheng Petrochemical Co., Ltd. Zhejiang Petrochemical Co., LTD

Zhejiang Petrochemical Co., LTD -

Pilot thin

Pilot thin Jiangxi Tungsten Industry

Jiangxi Tungsten Industry

-

Comprehensive Laboratory for Material Handling

Committed to basic and applied research in the process industry

and driving the efficient innovation and application of new equipment, new materials and new processes.

65%Engineering R&D Personnel170+Patents & Qualifications6+University Cooperation -

Shenzhen Redcoast

Committed to basic and applied research in the process industry and driving the efficient innovation and application of new equipment, new materials and new processes.

65%Engineering R&D Personnel170+Patents & Qualifications6+University Cooperation

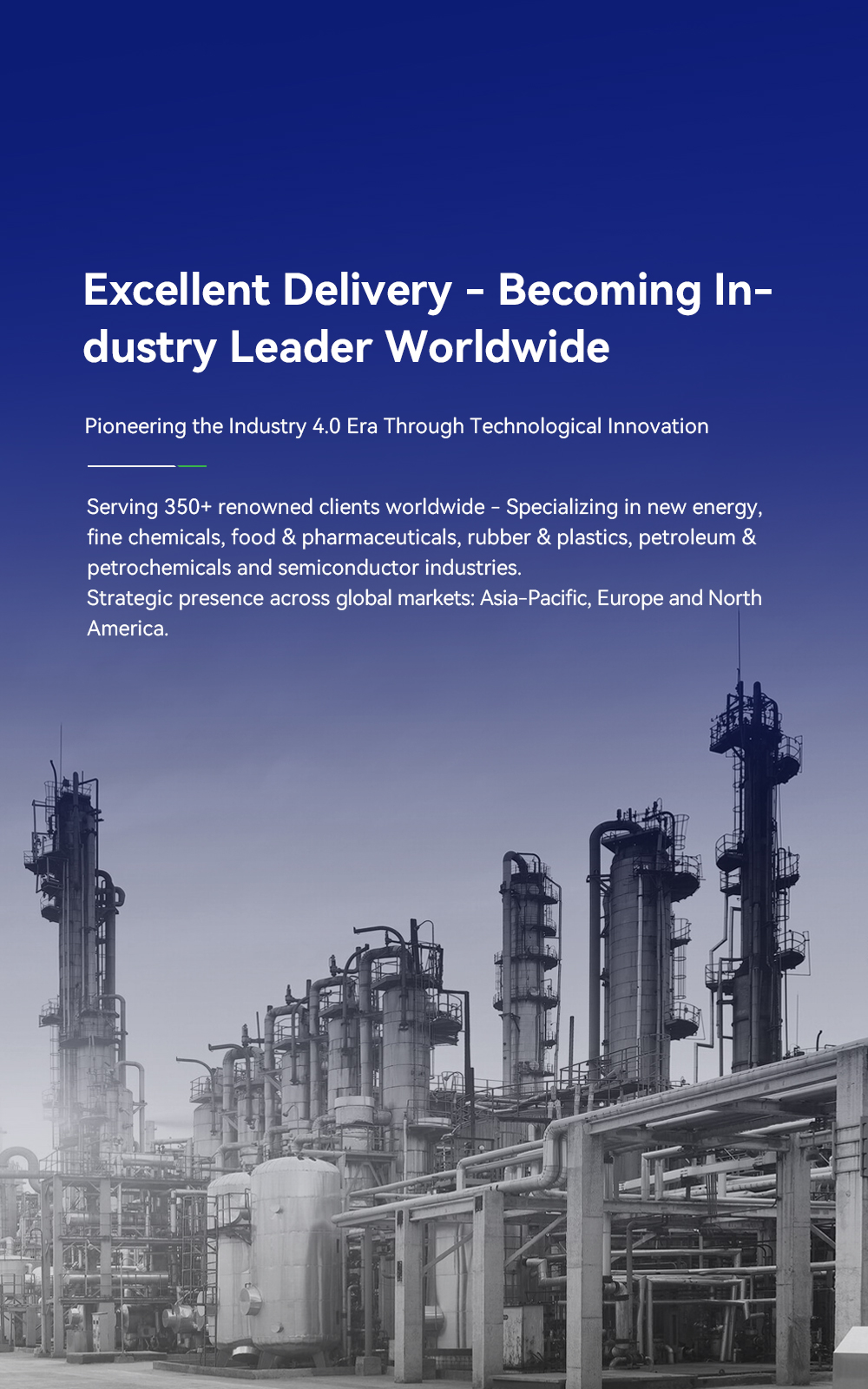

Committed to becoming a world-leading service provider of material handling technologies and upholding forward R&D philosophy in materials and processes, SOPHON provides integrated solutions for the process industry and covers service systems such as advanced design, advanced manufacturing, and advanced operation and maintenance management. Our solutions are widely applied in industries including new energy, new materials, chemical plastics, food, pharmaceuticals, semiconductors, petroleum and petrochemicals.

-

SOPHON Updates【SOPHON GOOD NEWS】Guangdong SOPHON Recognized as Certified Supplier for the Petrochemical Industry in China

SOPHON Updates【SOPHON GOOD NEWS】Guangdong SOPHON Recognized as Certified Supplier for the Petrochemical Industry in China SOPHON Updates2025.03.28【SOPHON】University-Enterprise Collaboration | Guangdong SOPHON and South China University of Technology Joint Laboratory InauguratedOn October 19th, Guangdong SOPHON and South China University of Technology (SCUT) successfully held the signing and inauguration ceremony for the Joint Laboratory for Powder Surface Technology Research and Application, marking a new chapter in university-enterprise collaboration and the integration of industry, academia, research and application.

SOPHON Updates2025.03.28【SOPHON】University-Enterprise Collaboration | Guangdong SOPHON and South China University of Technology Joint Laboratory InauguratedOn October 19th, Guangdong SOPHON and South China University of Technology (SCUT) successfully held the signing and inauguration ceremony for the Joint Laboratory for Powder Surface Technology Research and Application, marking a new chapter in university-enterprise collaboration and the integration of industry, academia, research and application. SOPHON Updates2025.03.28【SOPHON】Event Review | SOPHON Shines at Shenzhen Nuclear Expo, Showcasing Cutting-edge Solutions for Nuclear Power RevolutionFrom November 11th to 13th, Shenzhen became the global focal point of the nuclear energy industry as the 3rd China High-Quality Nuclear Development Conference & Shenzhen International Nuclear Innovation Expo (hereinafter referred to as "Nuclear Expo") was grandly convened. At this prestigious gathering of industry elites and intellectual exchange, Guangdong SOPHON successfully captured attendees' attention through its exceptional innovation capabilities and profound technological expertise.

SOPHON Updates2025.03.28【SOPHON】Event Review | SOPHON Shines at Shenzhen Nuclear Expo, Showcasing Cutting-edge Solutions for Nuclear Power RevolutionFrom November 11th to 13th, Shenzhen became the global focal point of the nuclear energy industry as the 3rd China High-Quality Nuclear Development Conference & Shenzhen International Nuclear Innovation Expo (hereinafter referred to as "Nuclear Expo") was grandly convened. At this prestigious gathering of industry elites and intellectual exchange, Guangdong SOPHON successfully captured attendees' attention through its exceptional innovation capabilities and profound technological expertise. -

Technical Research【SOPHON】Technology Exploration | IBC-AGV Collaboration: Innovative Solutions for Rapid Formula Changeover and High-efficiency Cleaning

Technical Research【SOPHON】Technology Exploration | IBC-AGV Collaboration: Innovative Solutions for Rapid Formula Changeover and High-efficiency Cleaning Technical Research2025.03.28【SOPHON】Experimental Research | Deep Integration of Simulation and Experimentation Accelerates Industrial Production EfficiencyIn the ever-evolving tide of industrial production, every micro-optimization serves as a lever for revolutionary transformation. As a pioneer in process industrial innovation, SOPHON has identified the challenges and opportunities within mixing process in a forward-looking manner. Through the perfect integration of simulation analysis and experimental research, we are redefining mixing process solutions to achieve comprehensive upgrades in cost efficiency, operational speed and precision control.

Technical Research2025.03.28【SOPHON】Experimental Research | Deep Integration of Simulation and Experimentation Accelerates Industrial Production EfficiencyIn the ever-evolving tide of industrial production, every micro-optimization serves as a lever for revolutionary transformation. As a pioneer in process industrial innovation, SOPHON has identified the challenges and opportunities within mixing process in a forward-looking manner. Through the perfect integration of simulation analysis and experimental research, we are redefining mixing process solutions to achieve comprehensive upgrades in cost efficiency, operational speed and precision control. Technical Research2025.03.28【SOPHON】Experimental Research | Application of Vacuum Defoamer for Bubble Removal of CMC Gel SolutionsWith the rapid advancement of materials science, CMC (carboxymethyl cellulose) gel solutions have demonstrated broad application potential across various fields. However, the presence of bubbles in these solutions has consistently hindered their performance. To address this challenge, SOPHON conducted defoaming experiments to thoroughly investigate the practical performance of vacuum defoamer. The study aims to provide robust data support and a theoretical foundation for further optimization and wider adoption of vacuum defoaming technology.

Technical Research2025.03.28【SOPHON】Experimental Research | Application of Vacuum Defoamer for Bubble Removal of CMC Gel SolutionsWith the rapid advancement of materials science, CMC (carboxymethyl cellulose) gel solutions have demonstrated broad application potential across various fields. However, the presence of bubbles in these solutions has consistently hindered their performance. To address this challenge, SOPHON conducted defoaming experiments to thoroughly investigate the practical performance of vacuum defoamer. The study aims to provide robust data support and a theoretical foundation for further optimization and wider adoption of vacuum defoaming technology.