The customer is a leading enterprise in the energy and chemical sector in China, and also ranks among the Fortune Global 500. It integrates oil and gas exploration and development, refining and chemical production, as well as sales and services.

The customer needs to convert waste plastic into fuel oil, carbon black, and combustible gas with pyrolysis refining technology. This process requires SOPHON to perform full-process material handling in the front-end section of plastic pyrolysis.

Processes in the front-end section of waste plastic recycling in the charge of SOPHON: Processing of bulk bags/tank trucks (semi- or fully-automated) containing pre-treated plastic pellets, conveying system, storage silos, conveying system, deoxygenation, oxygen-free gravity feeding, precise metering, and automated process control.

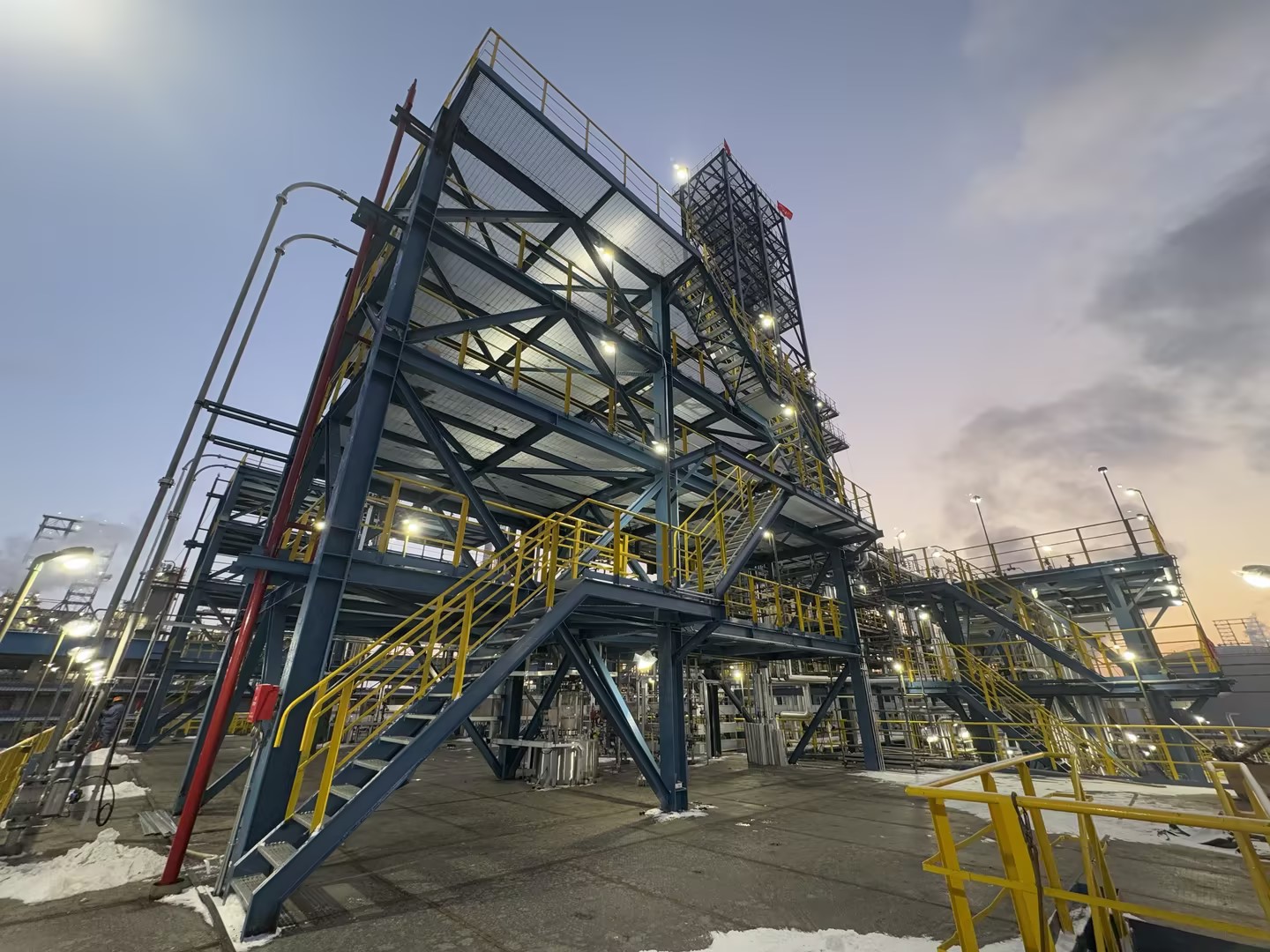

Confronting the challenges of waste plastic material processing, SOPHON collaborated with the customer to create the first waste plastic-to-oil reverse refining unit in the world. Building on theoretical data from Z-Source Laboratory and extensive prior experience, SOPHON proactively developed and customized a comprehensive solution for recyclable plastic processing, achieving significant technological innovations: The system adopts a floor-installed dust collector to effectively reduce dust pollution, utilizes drawer-style magnetic separators for precise impurity removal, and incorporates a unique deoxygenation buffer tank, triple explosion-proof design, two power sources with one in use and one on standby, and a pipeline system enabling instant switching. These features collectively ensure continuous and stable operation of the equipment for 8,400 hours.

The enterprise highly commended this solution and awarded SOPHON the honorary title of "Outstanding Supplier".

Latest Recommendations

Latest Recommendations