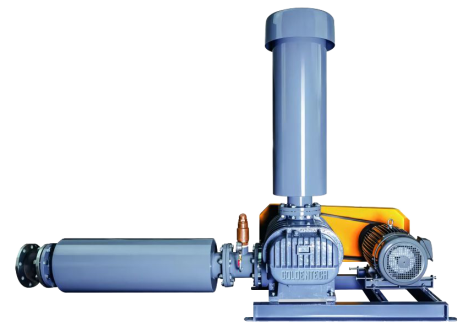

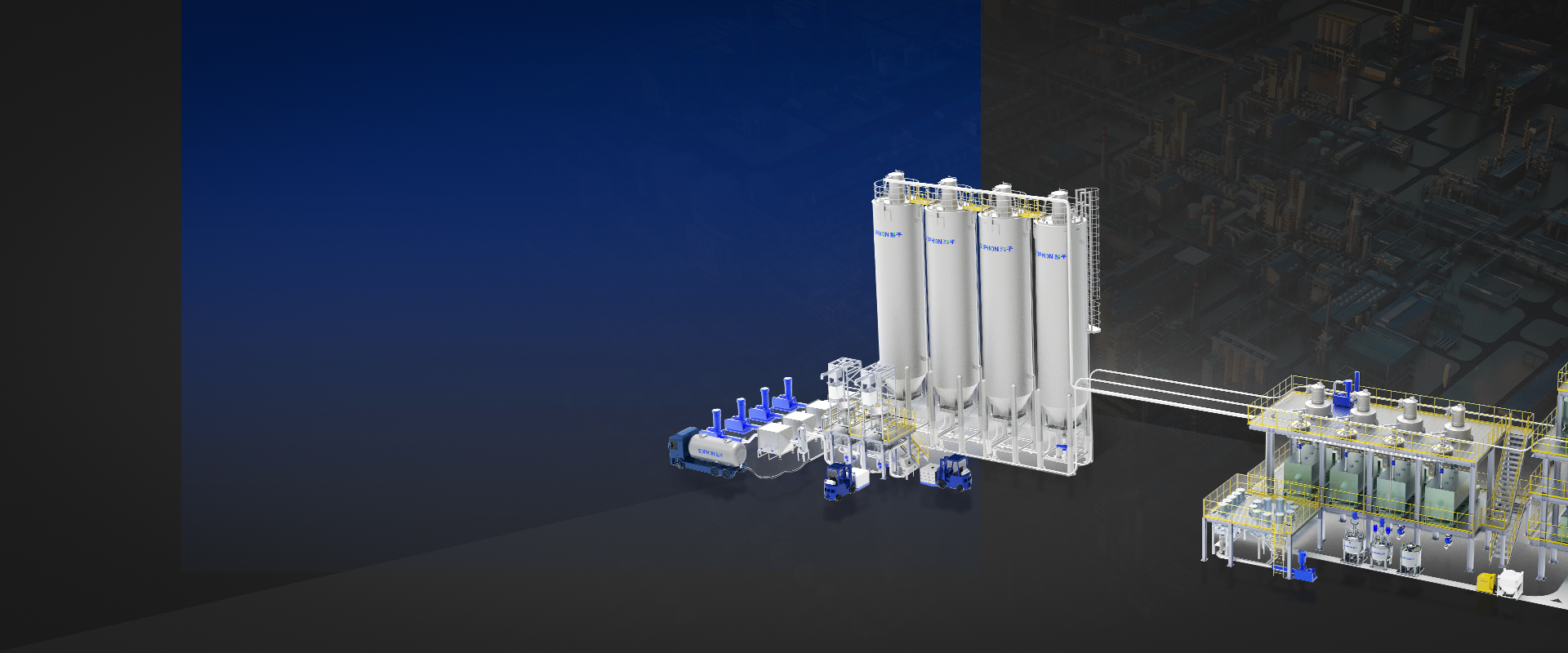

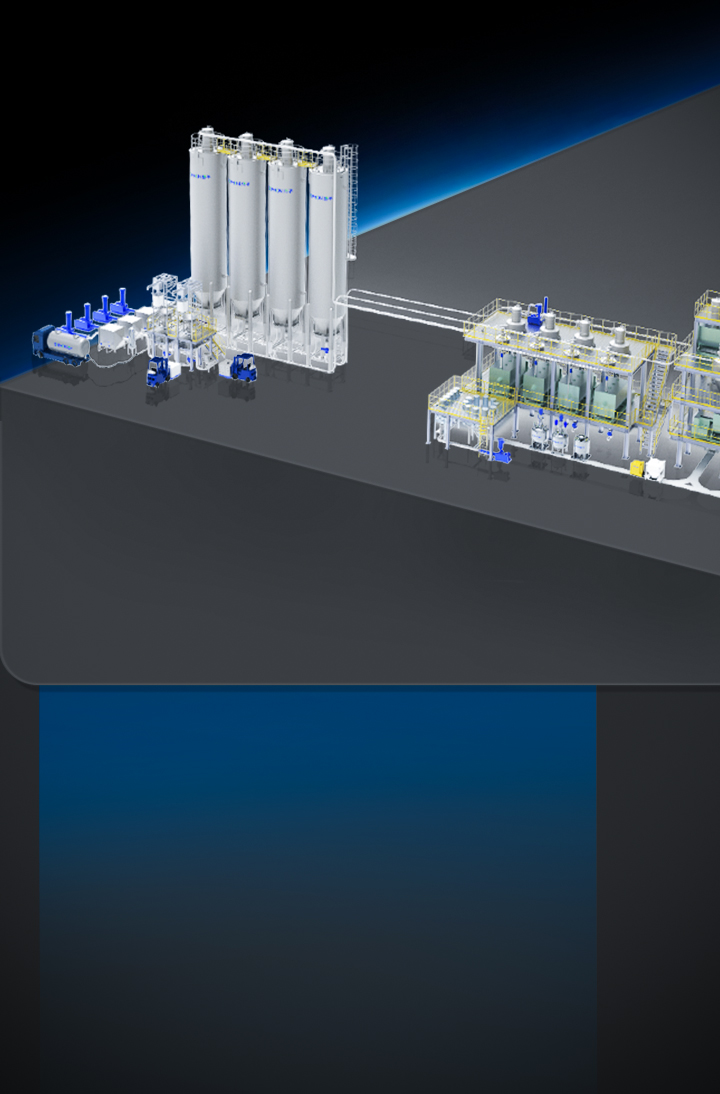

The pneumatic conveying system represents a highly-efficient, safe, and eco-friendly solution for bulk materials conveyance including powders, granules, liquid and slurry. Capable of meeting diverse industrial production requirements, this system finds extensive applications across multiple sectors such as chemicals, new energy, pharmaceuticals and food.

20% Production Efficiency Increased: Saves time and labor with high automation, significantly enhancing production efficiency;

20% Labor Cost Reduced: Only requires 1-2 operators for each production line; minimizes workforce and labor expenses;

Eco-Friendly & Healthy: Automated feeding with high-precision dust collectors and fully enclosed pipeline conveyance; free from dust emission to maintain workshop cleanliness;

Blockage-free & Easy Maintenance: Stable operation without clogging/leakage; simple structure for easy maintenance;

High-precision Metering: The accuracy of ingredient metering is up to 2%, improving the quality of products and reducing defect rate;

Easy Operation: Highly automated with intuitive control.

The system simultaneously performs metering, batching, screening, mixing, magnetic separating, and impurity removal during material conveying, thus satisfying specific production requirements of our clients.