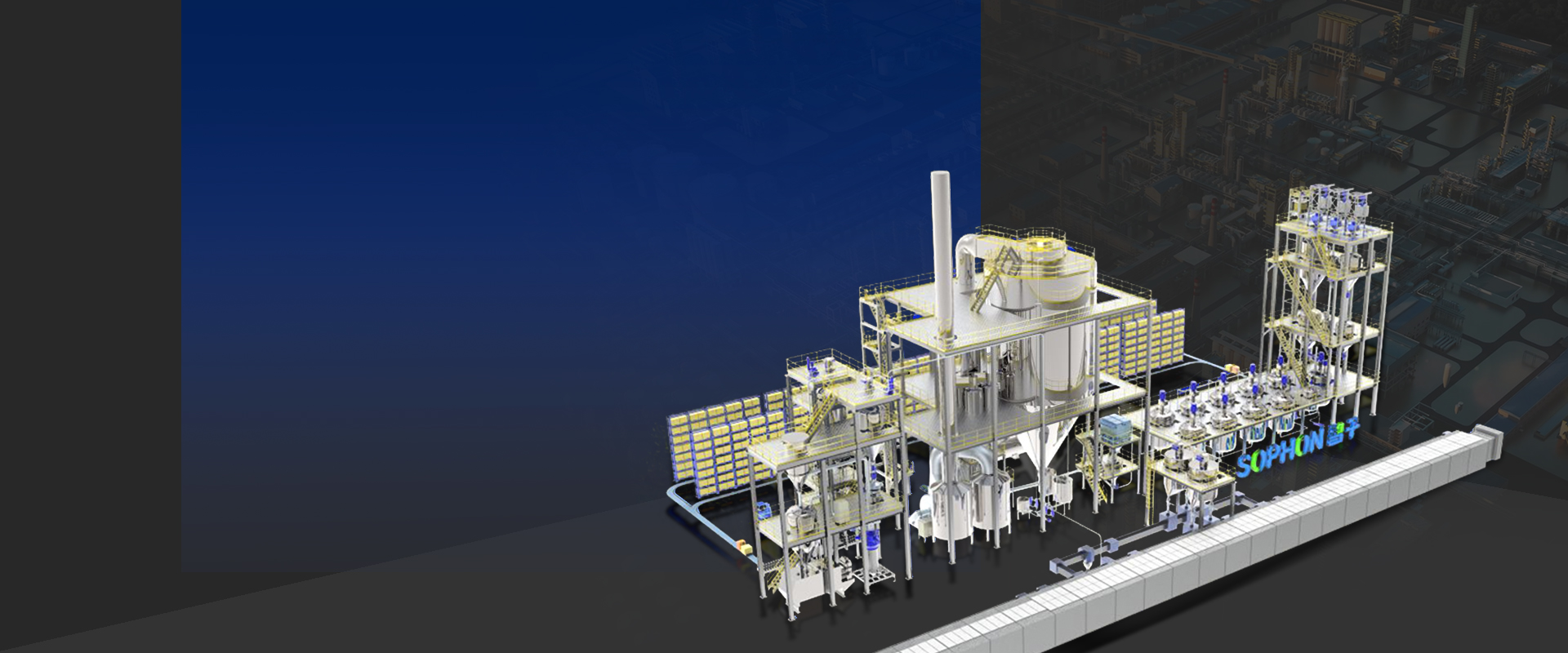

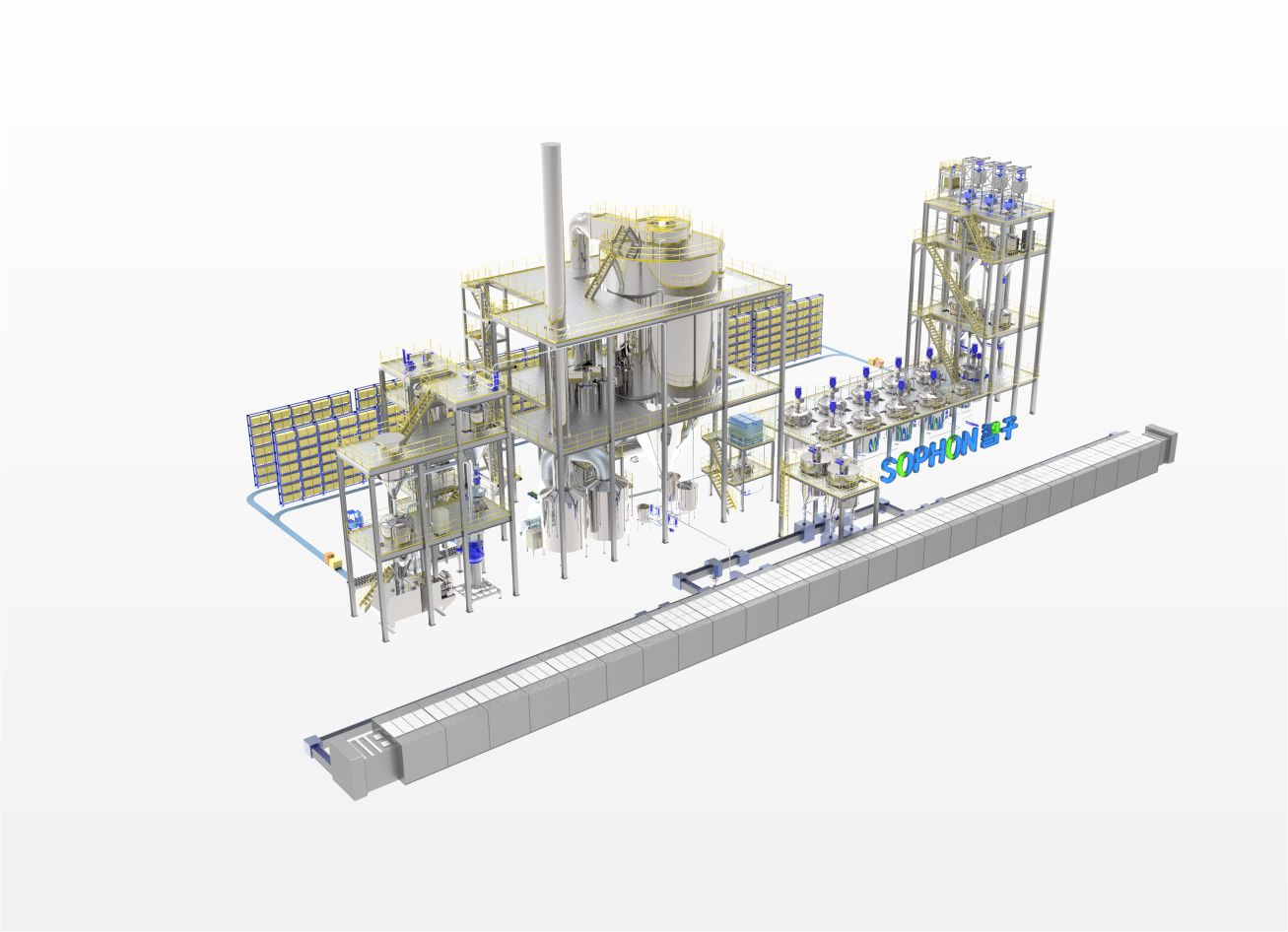

SOPHON provides fully-automatic systems for the unpacking, precise metering, and conveying of different lithium, carbon, and phosphate sources, and works out the equipment implementation plan for various process routes. For rear processes such as prilling, sintering, crushing, batch mixing, screening, magnetic separating, packaging, etc., we complete the implementation plan of fully-automatic production equipment and carry out lifecycle management of the production line.

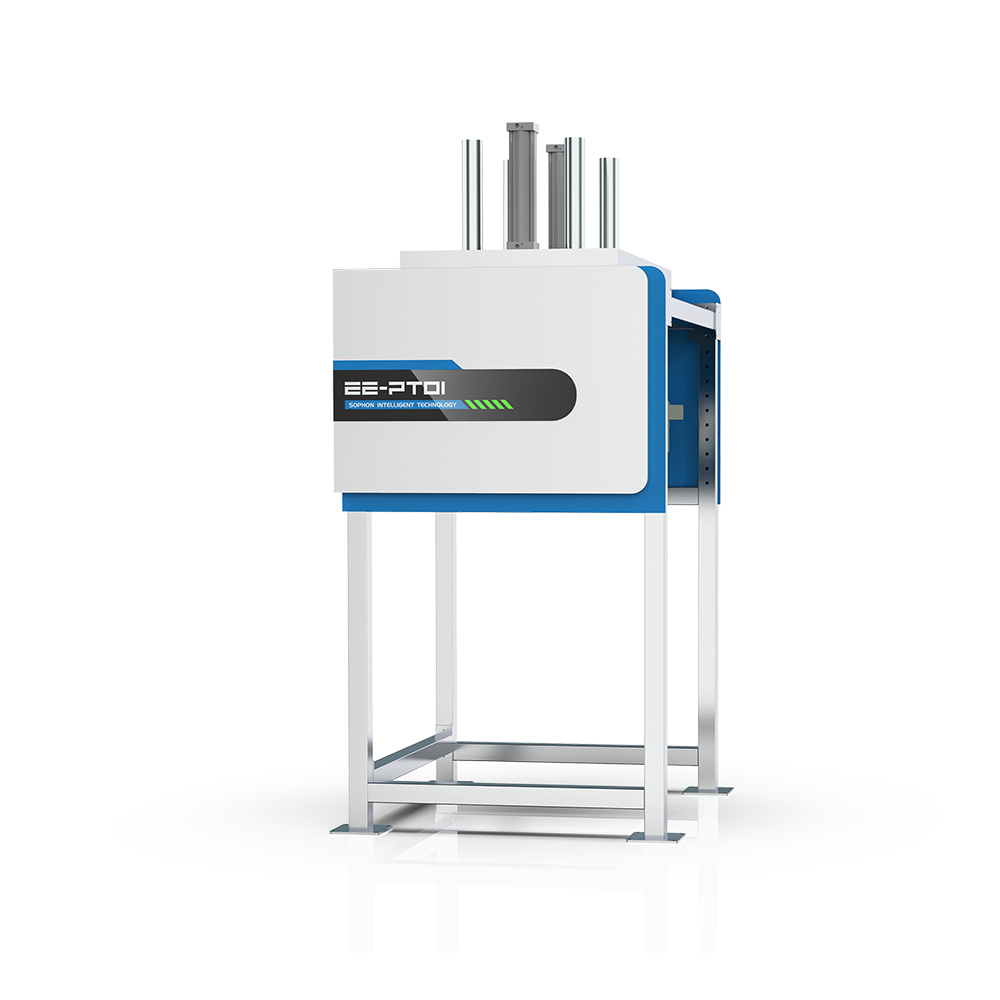

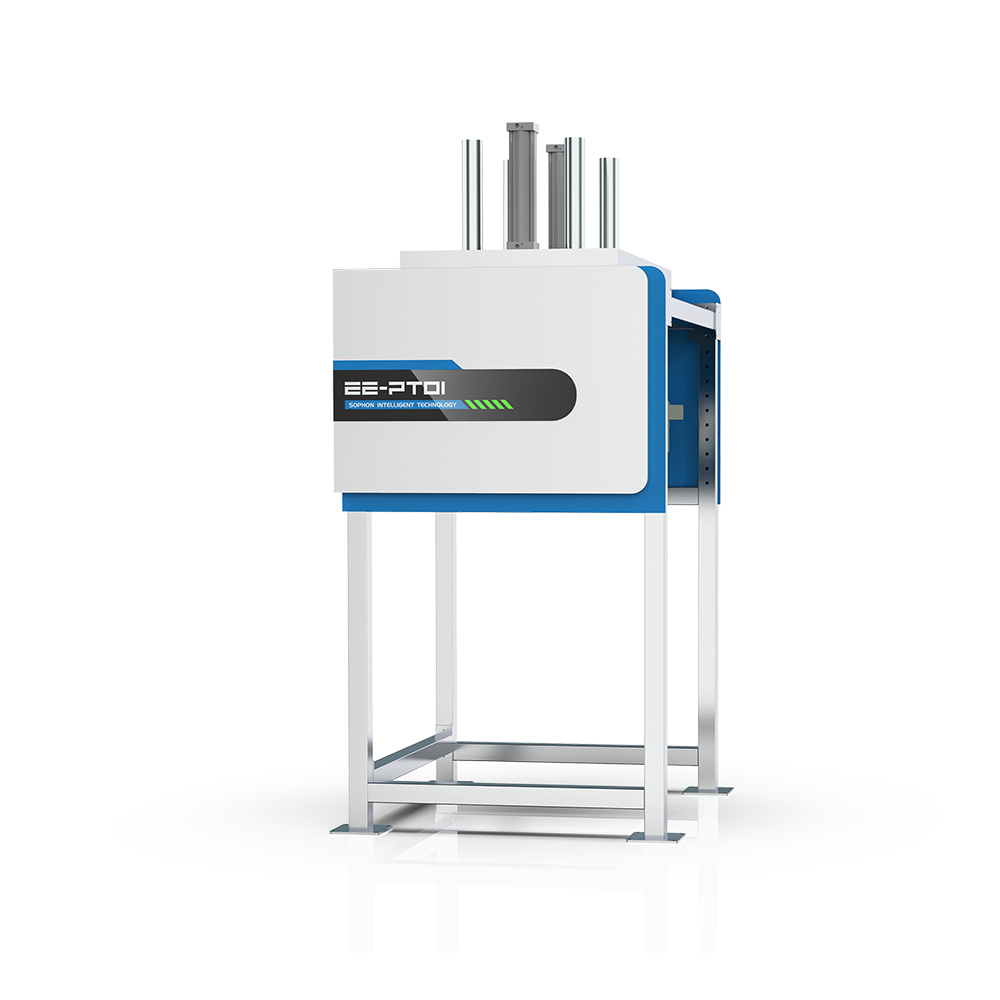

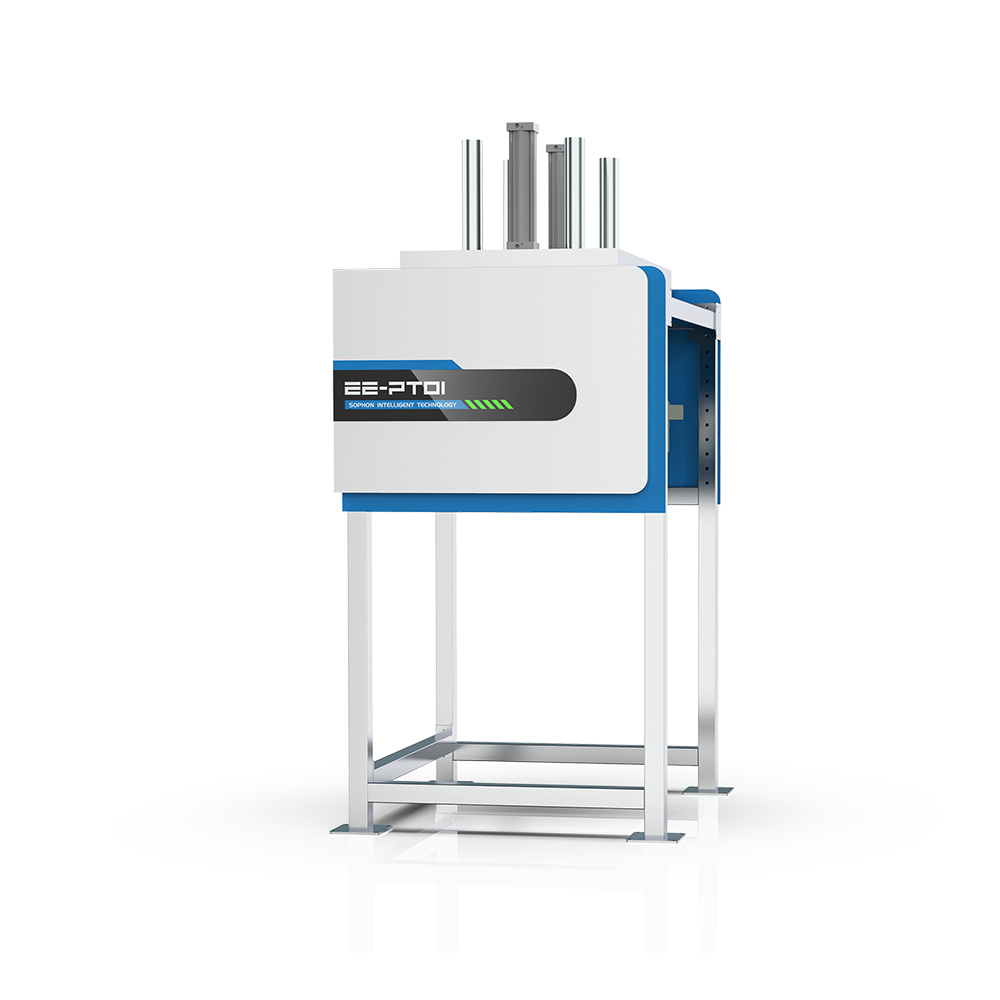

Dehumidification and consumption reduction; strong magnetic absorption; high screening accuracy; production efficiency; operation and maintenance costs reduction.

The system simultaneously performs metering, batching, screening, mixing, magnetic separating, and impurity removal during material conveying, thus satisfying specific production requirements of our clients.