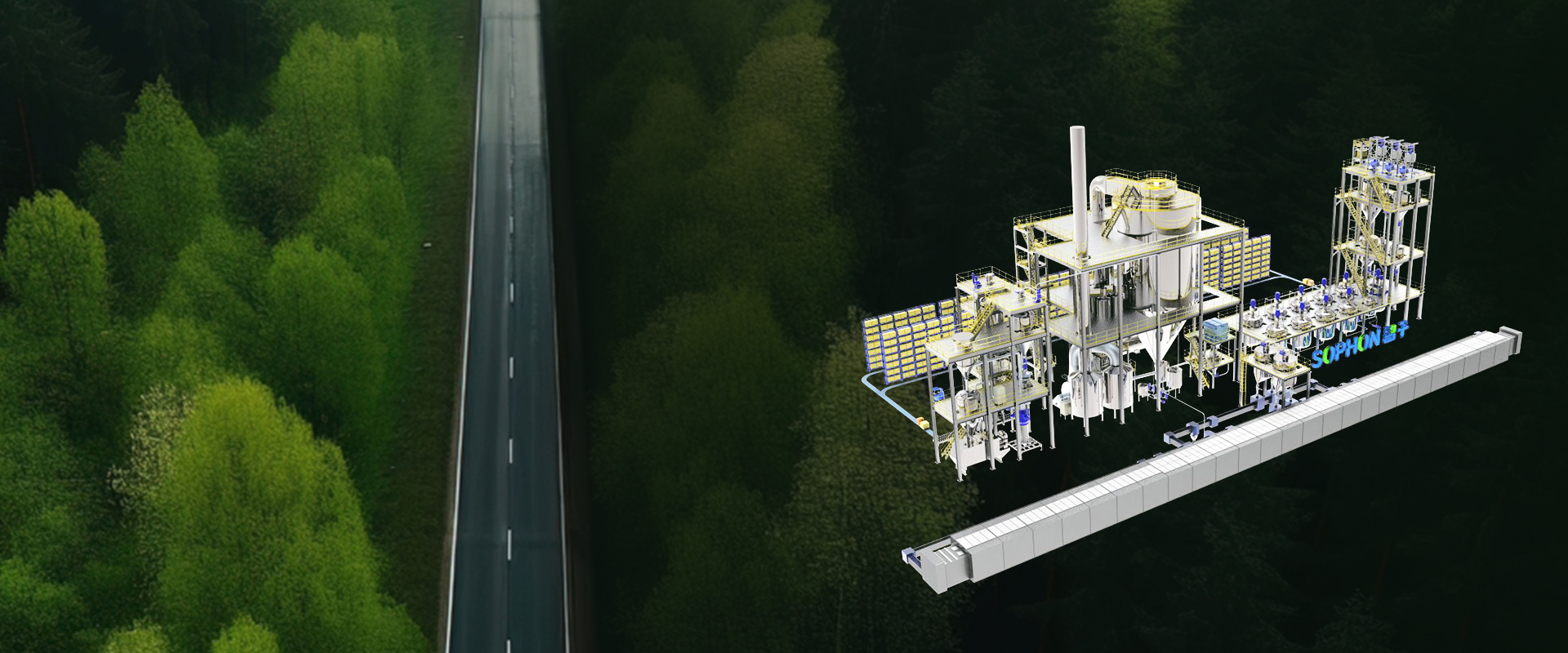

SOPHON provides fully-automatic unpacking and precise metering and conveying systems for different lithium, carbon and phosphate sources and works out the equipment production plan for various processes. For rear processes such as prilling, sintering, crushing, batch mixing, screening, magnetic separating, packaging, etc., we complete the implementation plan of fully-automatic production system and carry out full lifecycle management of the production line.

Speed up the Design Delivery Schedule: Configure production lines according to customers’ production schedules to ensure that equipment parts meet process requirements and improve overall production capacity.

Improve Production Efficiency: Through the rational configuration of automated equipment, manual intervention can be effectively reduced and remote control of the production line can be realized.

Reduce Operation & Maintenance Costs: According to the actual plant height and conveying distance requirements, different pneumatic conveying methods are provided. Moreover, valve control is adopted to realize flexible configuration of one on standby and one in use, thus optimizing the overall layout design of the system.