Filling and Packaging System

Process Overview:

The filling and packaging system utilizes high-precision measuring devices and control systems to ensure each packaged unit meets predetermined quality and quantity standards.

For instance, automatic quantitative filling machines employ measurement instruments such as electronic scale and flow meter to precisely control filling volumes, minimizing waste while guaranteeing product quality stability and consistency.

Consult Now

Advantages

Precise Metering & Efficient Packaging

Intelligent Operation

Optimize Production Efficiency & Lower Costs

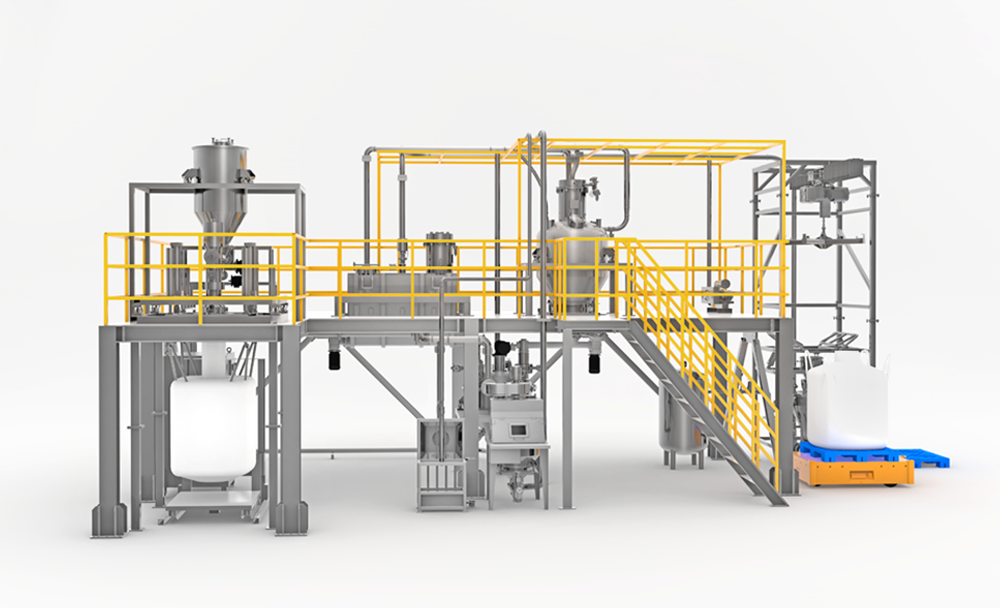

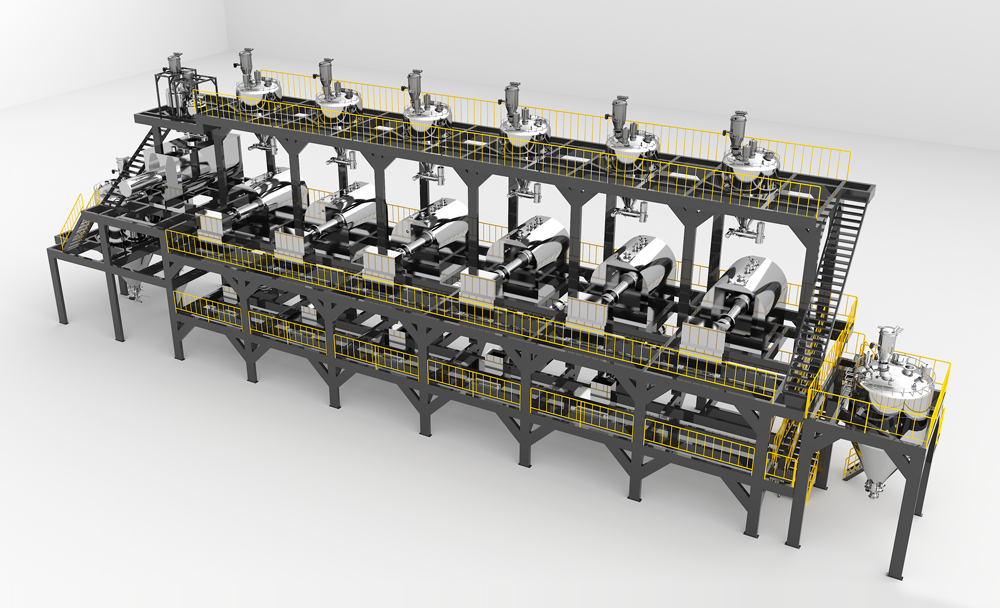

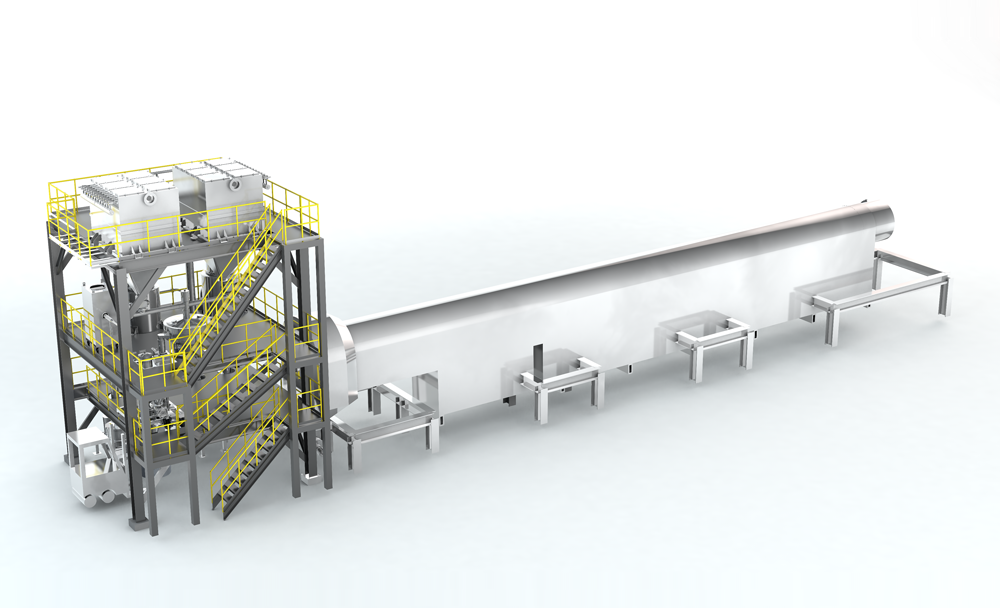

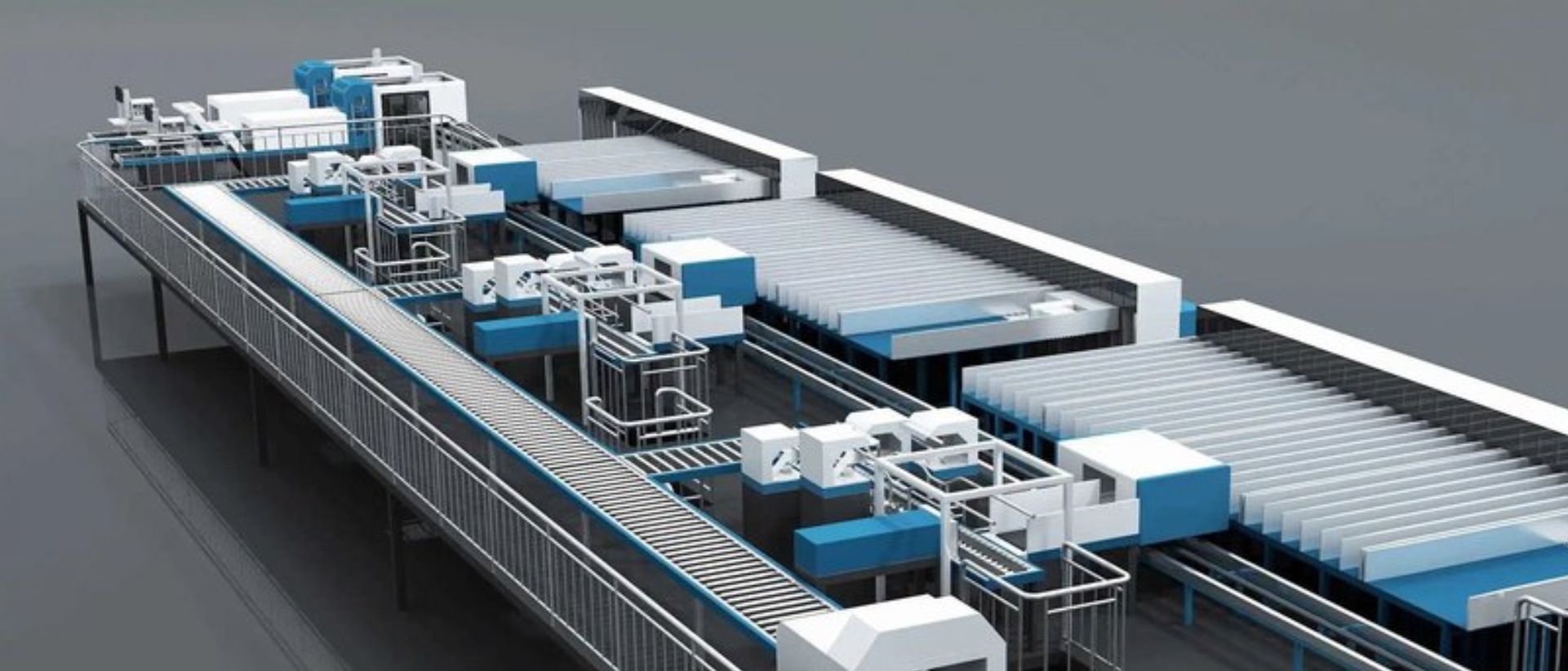

System 3D Diagram

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement