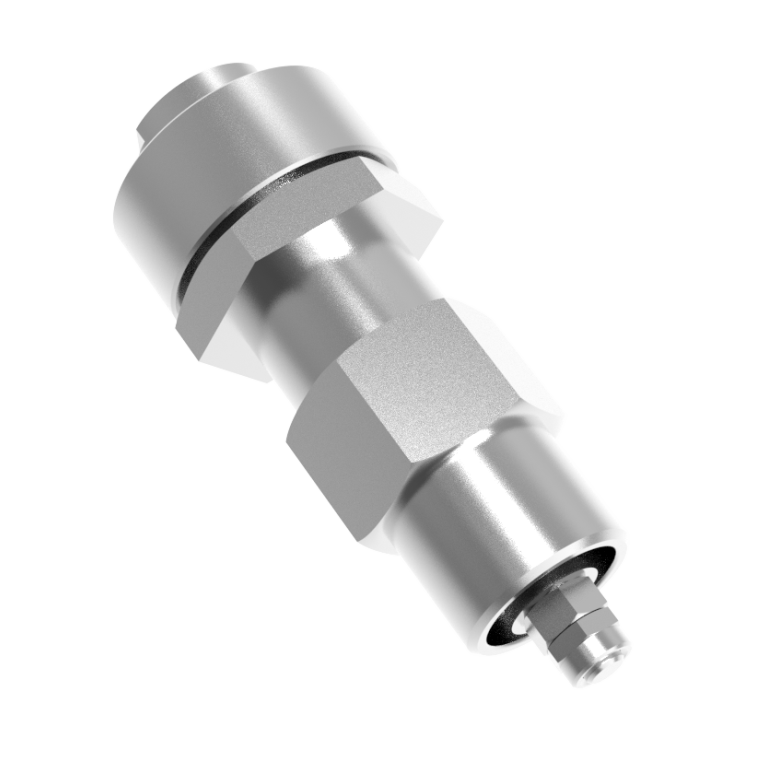

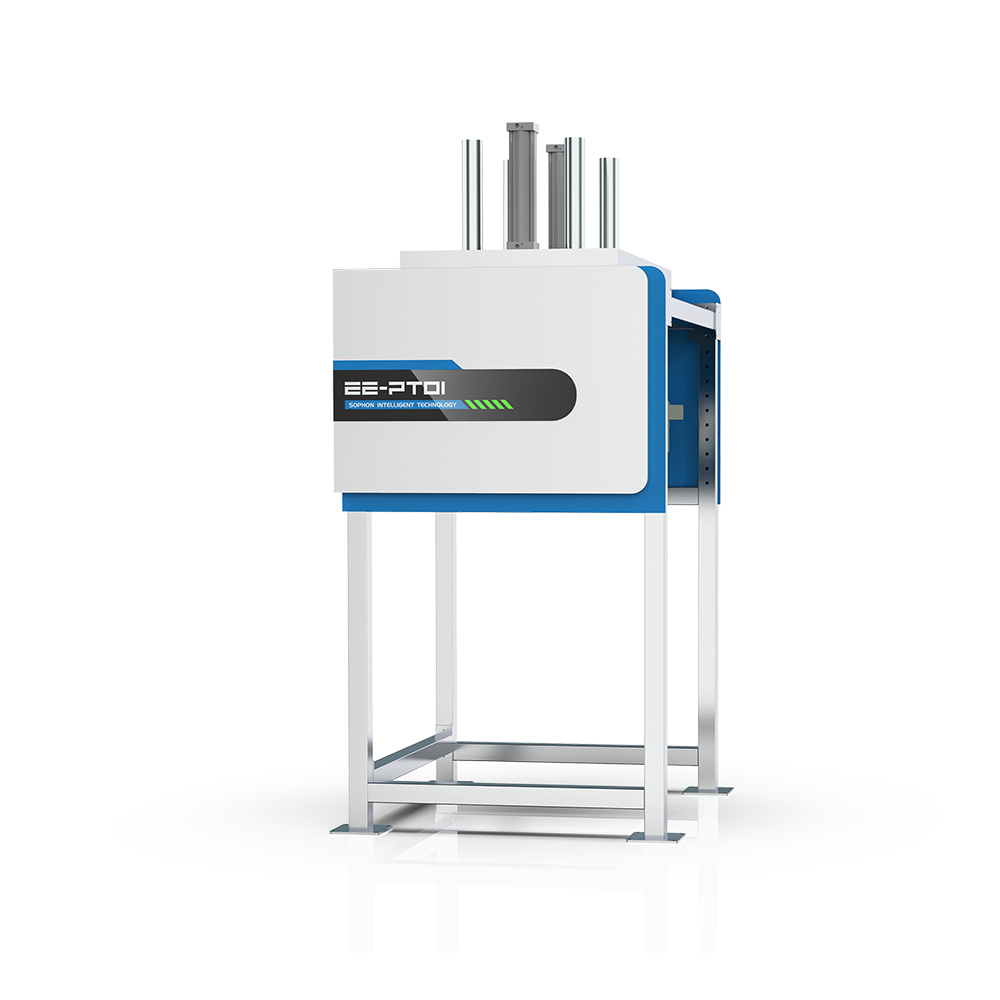

Jet Arch Breaker

The Jet Arch Breaker is a non-contact and intelligent arch-breaking device designed to resolve persistent blockage, such as bridging, ratholing, and material stagnation, during the storage and conveyance of low-fluidity materials including powders and granules.

Consult Now

工作原理

利用真空泵抽气,使吸料嘴(进料口)及整个系统处于一定的真空状态。在此负压条件下,颗粒或粉末状物料随同外界空气被吸入料嘴,形成连续的料气流。此料气流沿着密闭的吸料管到达料斗,并在料斗中进行气、料分离。分离后的物料最终进入受料设备。

Product Advantages

Applicable Fields

Applicable Materials

Powder Materials

Granular Materials

Blocky Materials

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement