Solutions in the New Material Industry

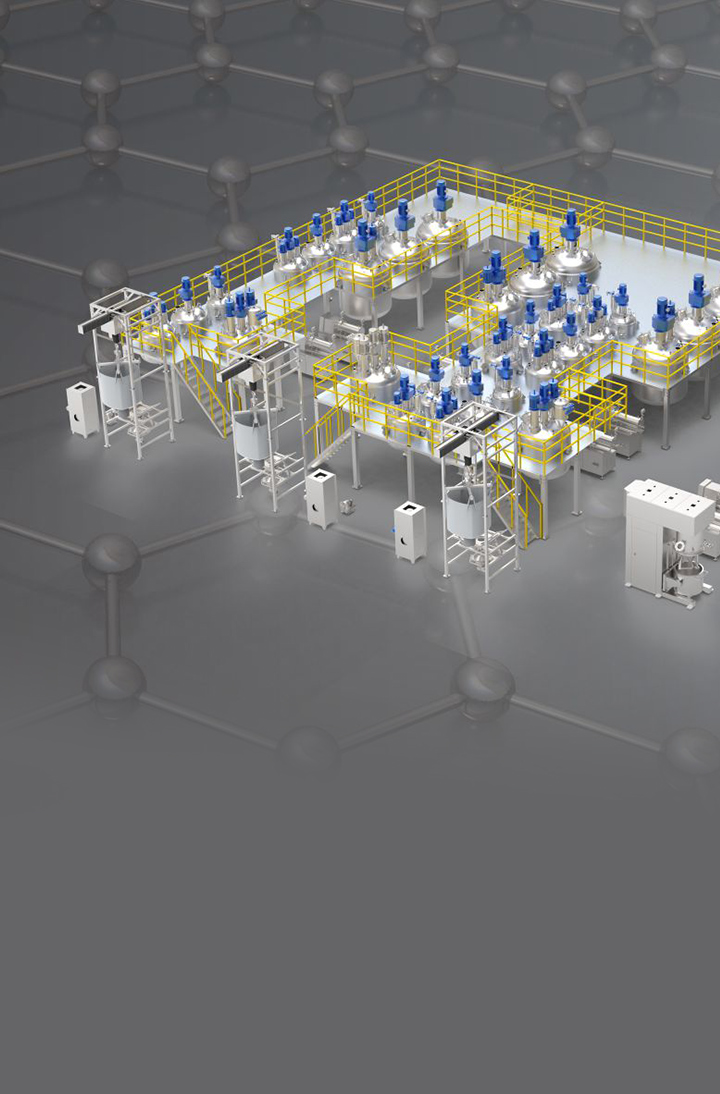

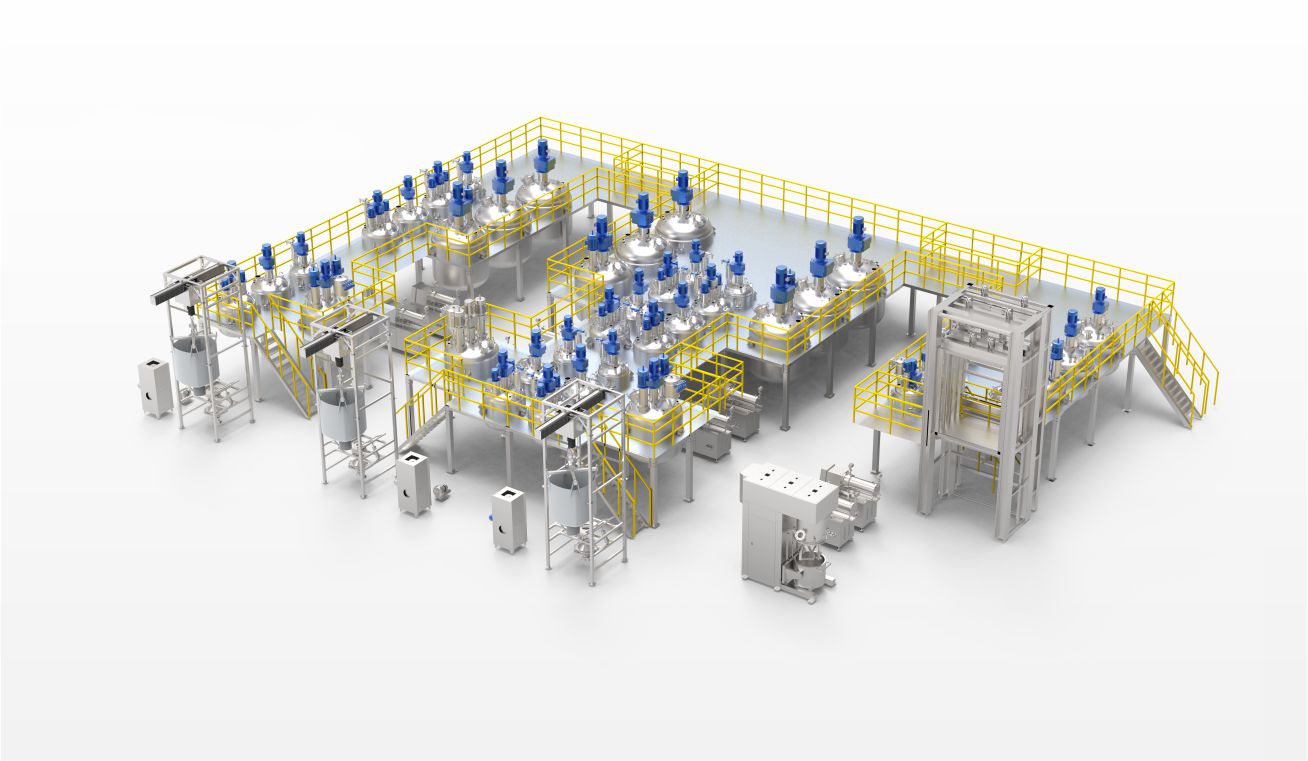

During the production of new materials, conveying lines, conveying equipment, external rail systems and circulation lines play critical roles. These systems are responsible for the efficient and secure conveyance of raw materials, intermediates, and finished products throughout all production stages. Modern conveying systems and conveying equipment integrate automated and smart technologies to ensure material stability (both physical and chemical properties) during transfer and minimize product loss and contamination risks.

Client's Pain Points

Inadequate equipment compatibility

Insufficient process control precision

High energy consumption and material loss

Uncontrollable maintenance and operation costs

Advantages

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement