Liquid Conveying System

Introduction

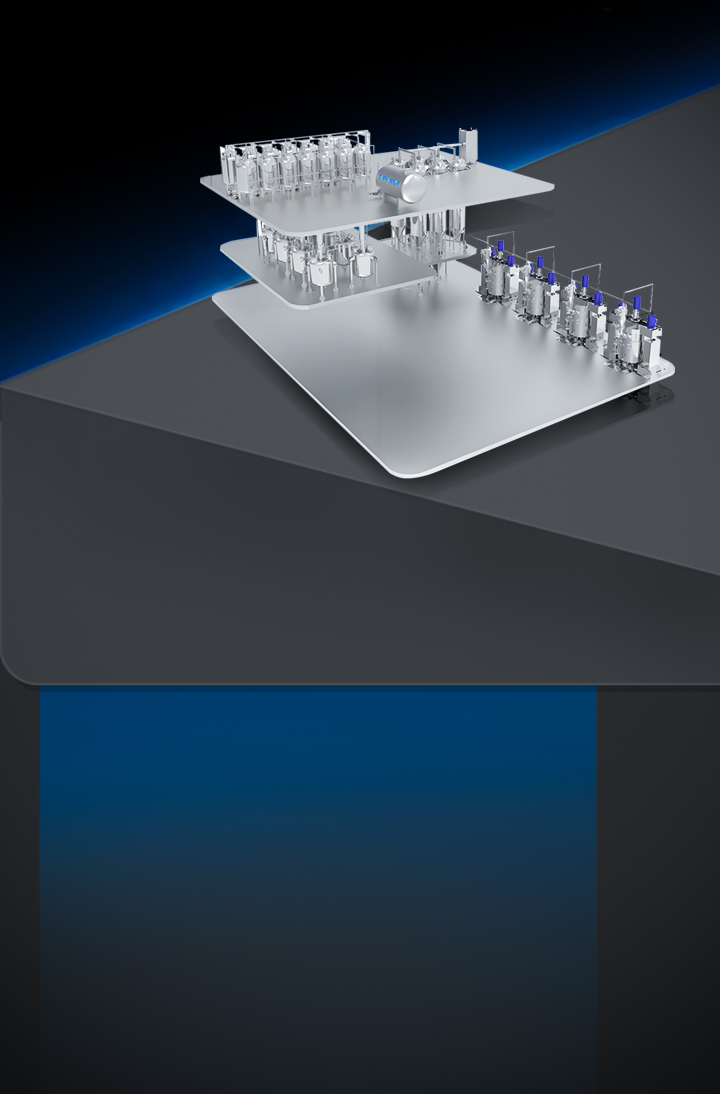

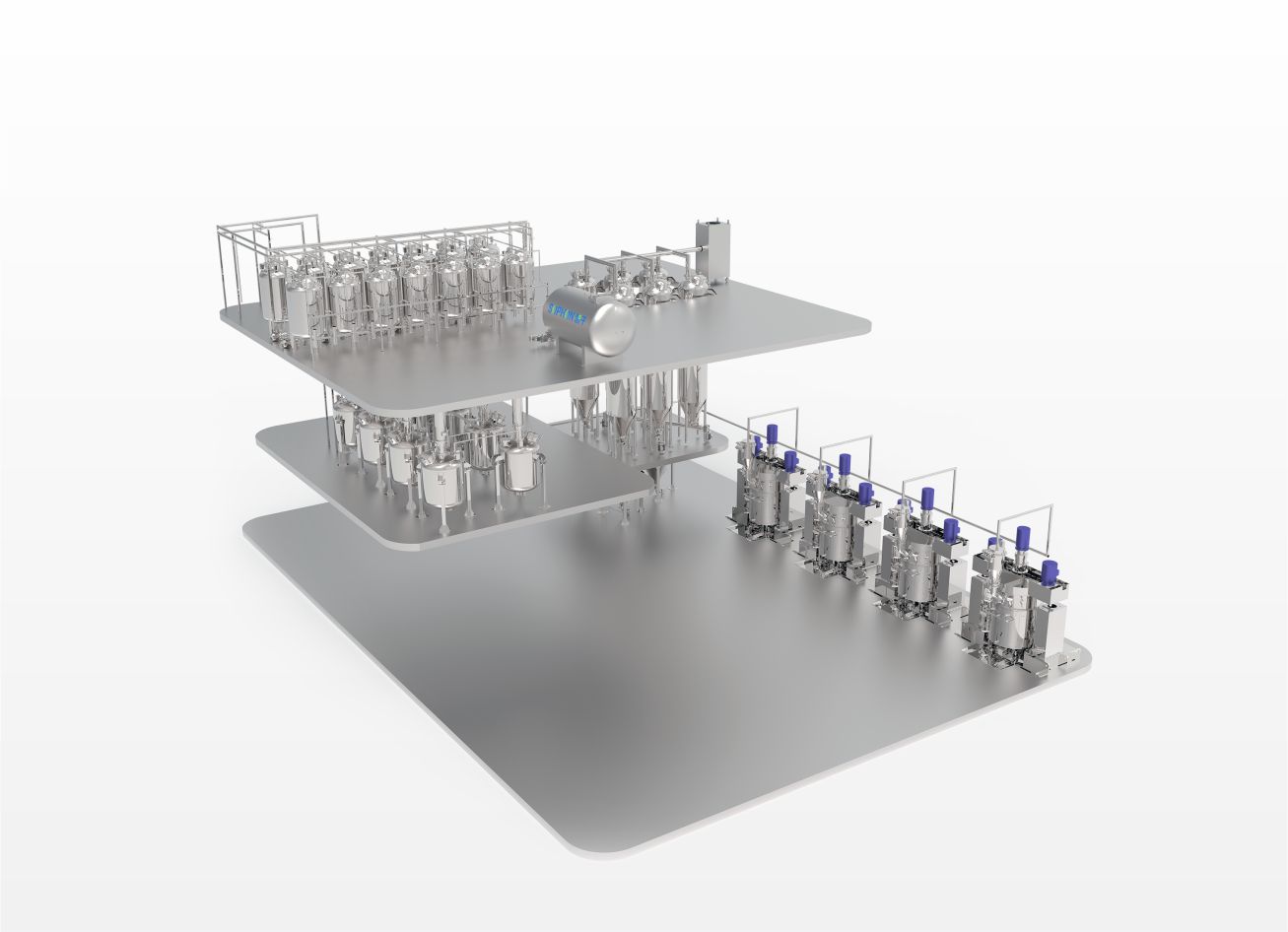

Designed to meet liquid batching process requirements and integrated with advanced automated control system, the liquid conveying system fulfills multiple processes including material feeding, conveying, temperature control, filtration, preparation, sterilization, and cooling. The system can significantly enhance labor productivity, reduce manpower costs, and ensure simple yet reliable operation.

System Advantages

High-efficiency conveying; eco-friendly and safe operation; exceptional flexibility; highly automated.

Liquid Conveying System Cases

Products Applied for Liquid Conveying System

The system simultaneously performs metering, batching, screening, mixing, magnetic separating, and impurity removal during material conveying, thus satisfying specific production requirements of our clients.

Metering Tank

Storage Tank

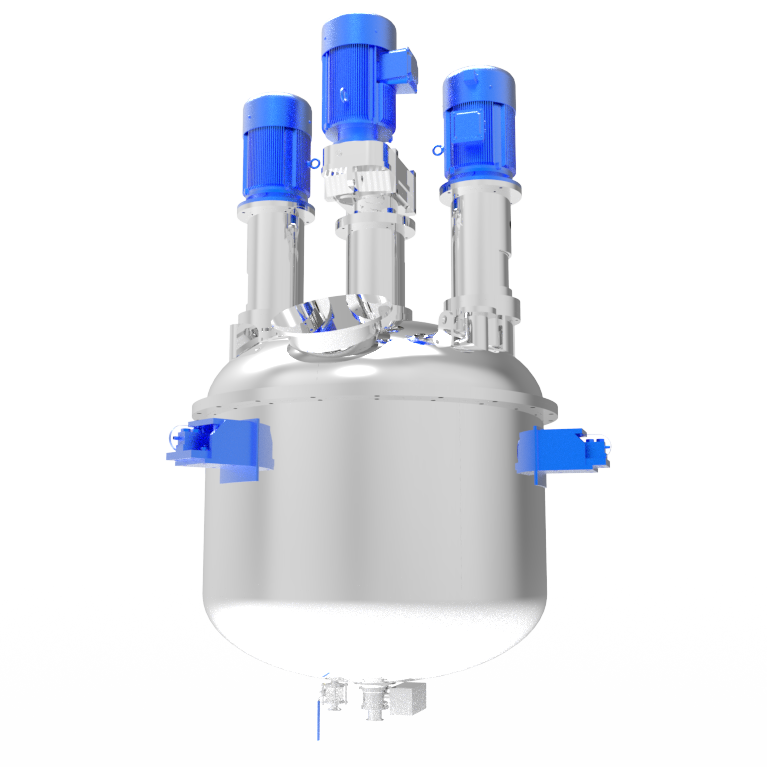

Mixing & Dispersing Tank

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement