The automatic feeding system is a technology that uses automated equipment to deliver materials into packaging containers or production equipment. It is widely applied in various production environments to improve efficiency and product quality.

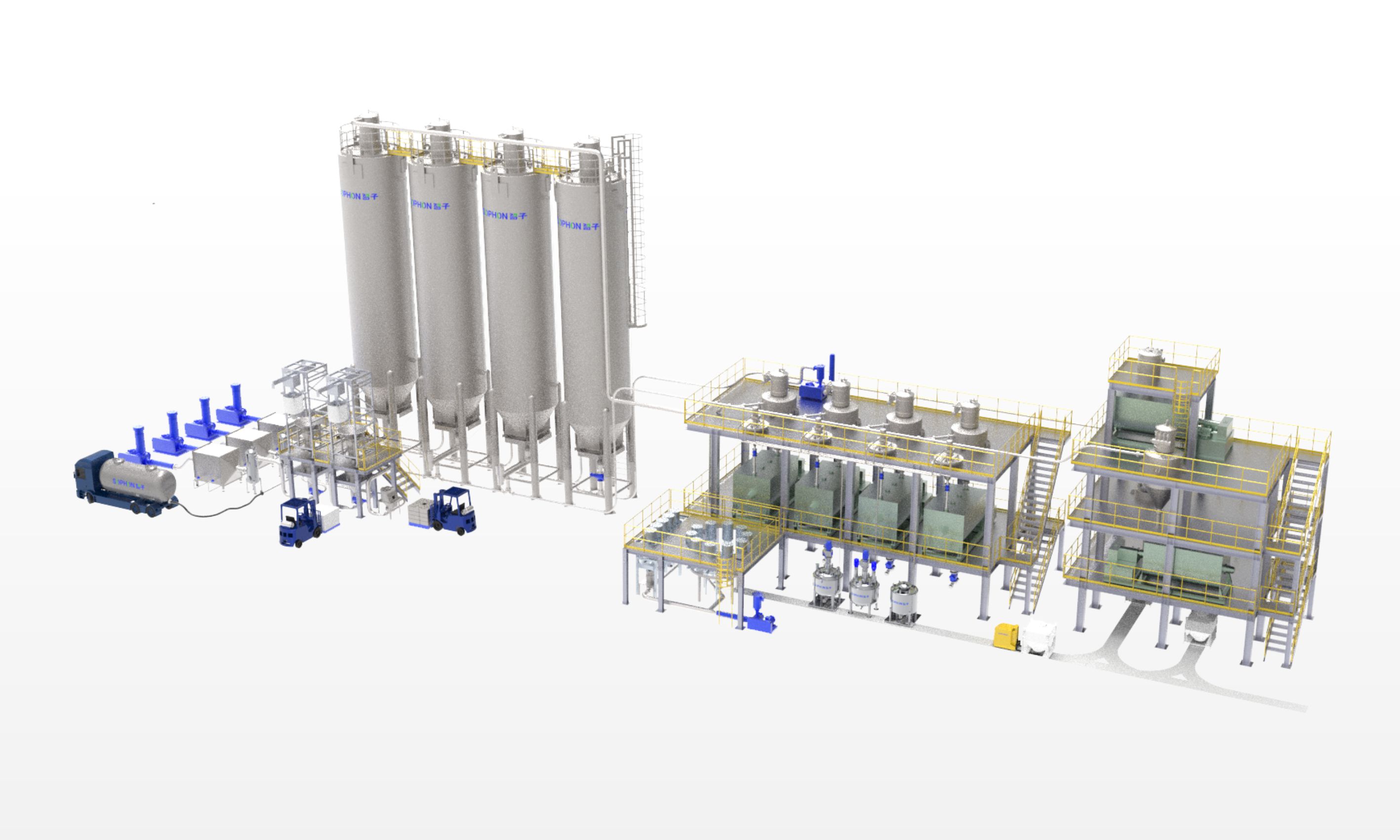

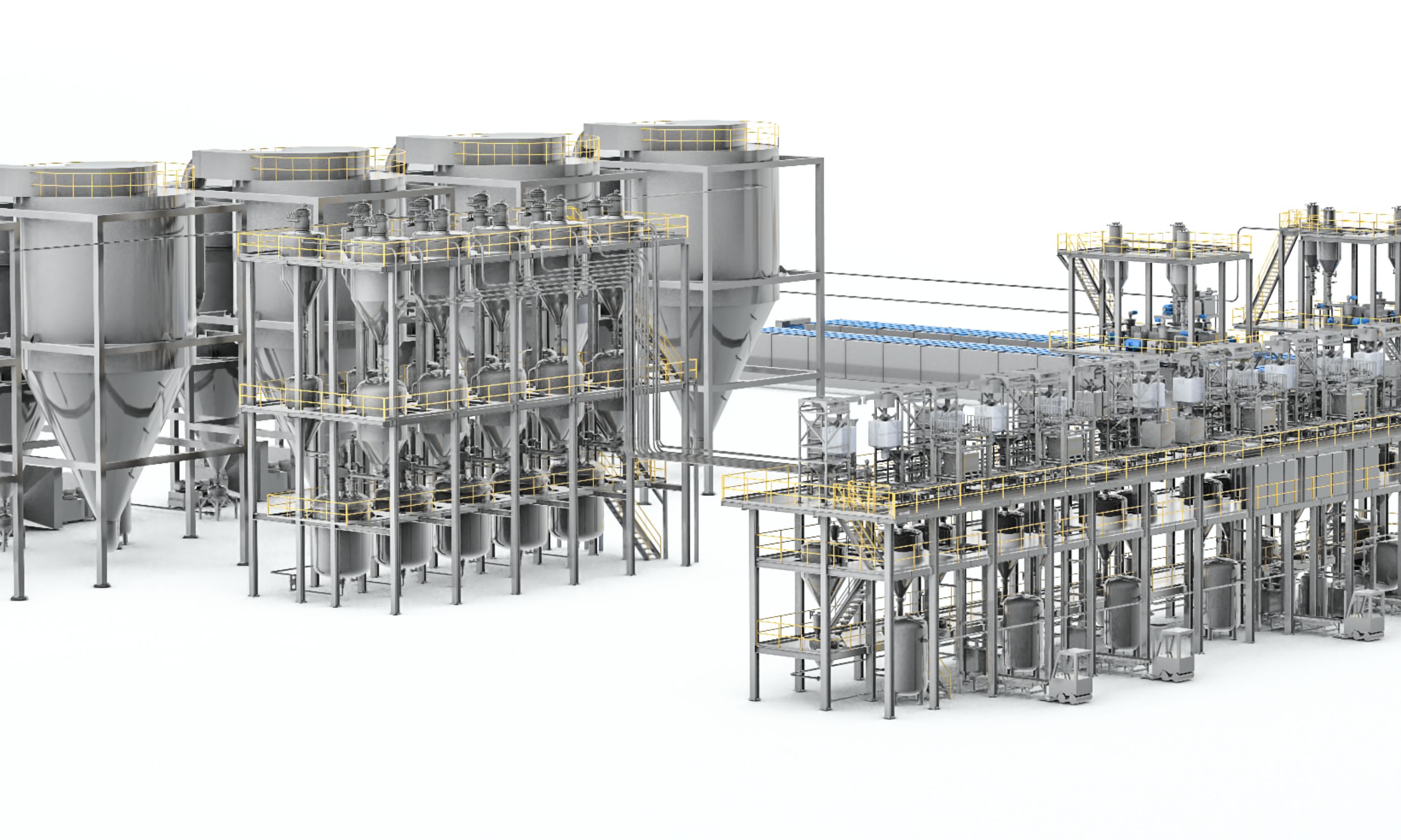

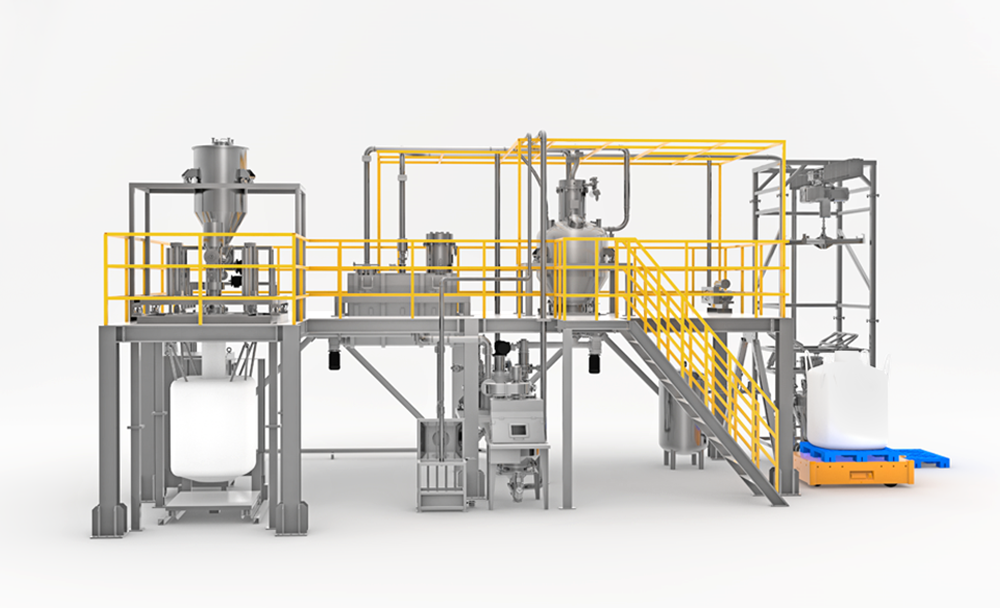

The pneumatic conveying system is a technology that utilizes airflow energy to convey powdered or granular materials through enclosed pipelines, representing specific application of fluidization technology. It adopts specialized feeding devices to introduce materials into the pipeline at controlled rates and deliver materials to designated locations with positive or negative pressure gases (such as air, nitrogen or carbon dioxide). The system ensures all conveying equipment and instruments operate automatically, orderly and safely under centralized control.

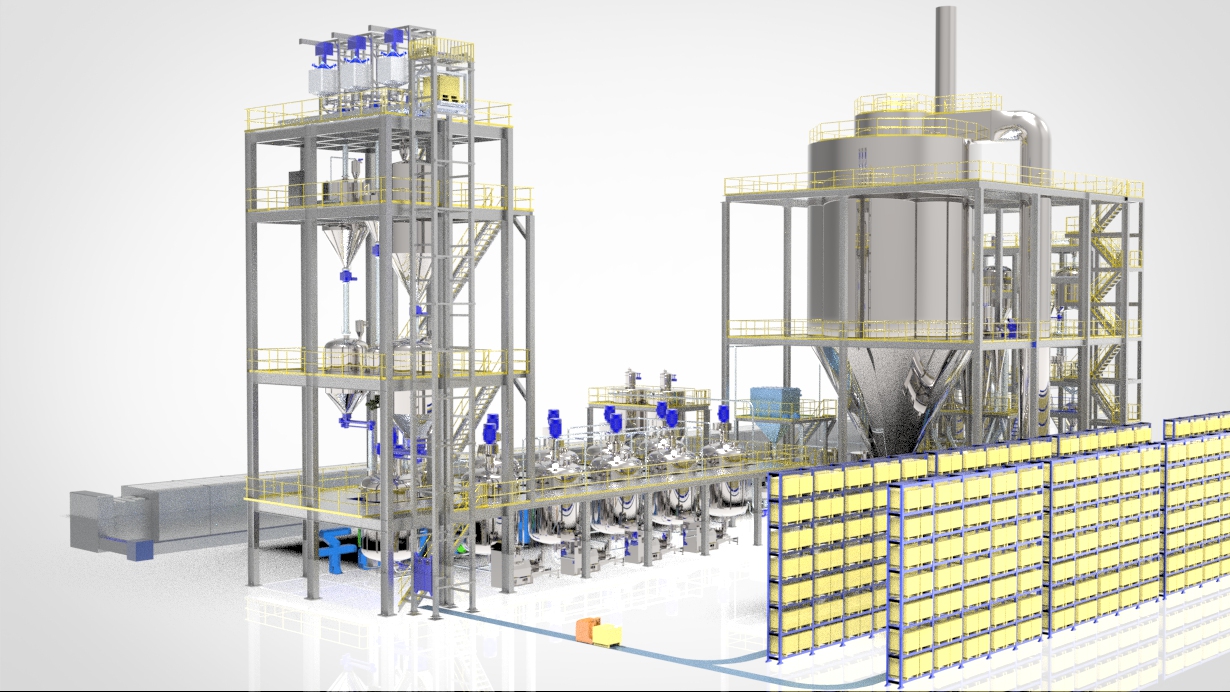

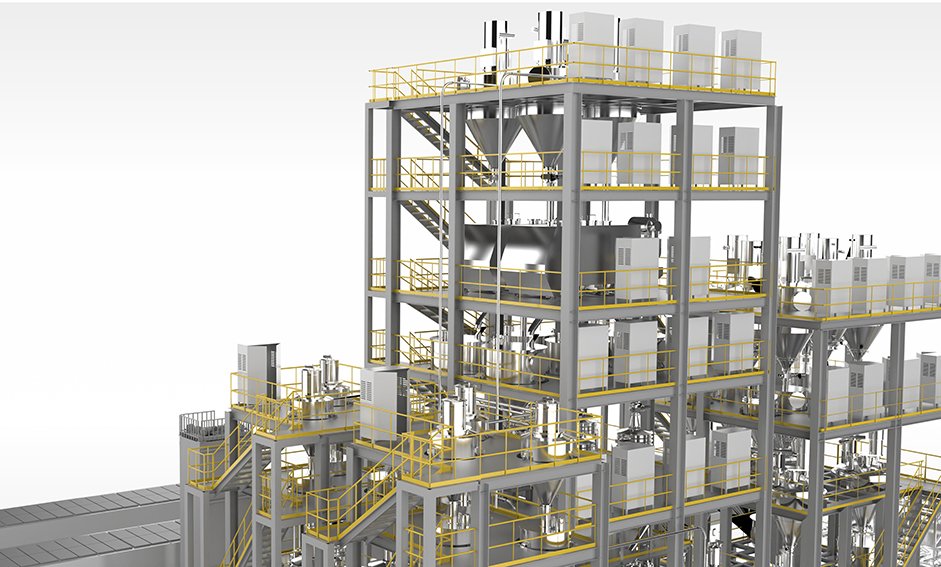

The weighing and dosing system can automatically complete the weighing and metering of various materials in multiple silos according to the formula requirements, providing customers with stable, reliable, precise and efficient weighing and dosing of materials.

The automatic dosing system is a core process in process industries (such as chemical, building materials, food, feed, new material preparation, etc.) that enables precise material dosing, automated feeding, and mixing. Its primary objectives are to replace manual batching, ensure metering accuracy, improve production efficiency, reduce material waste, and achieve traceability throughout the production process.

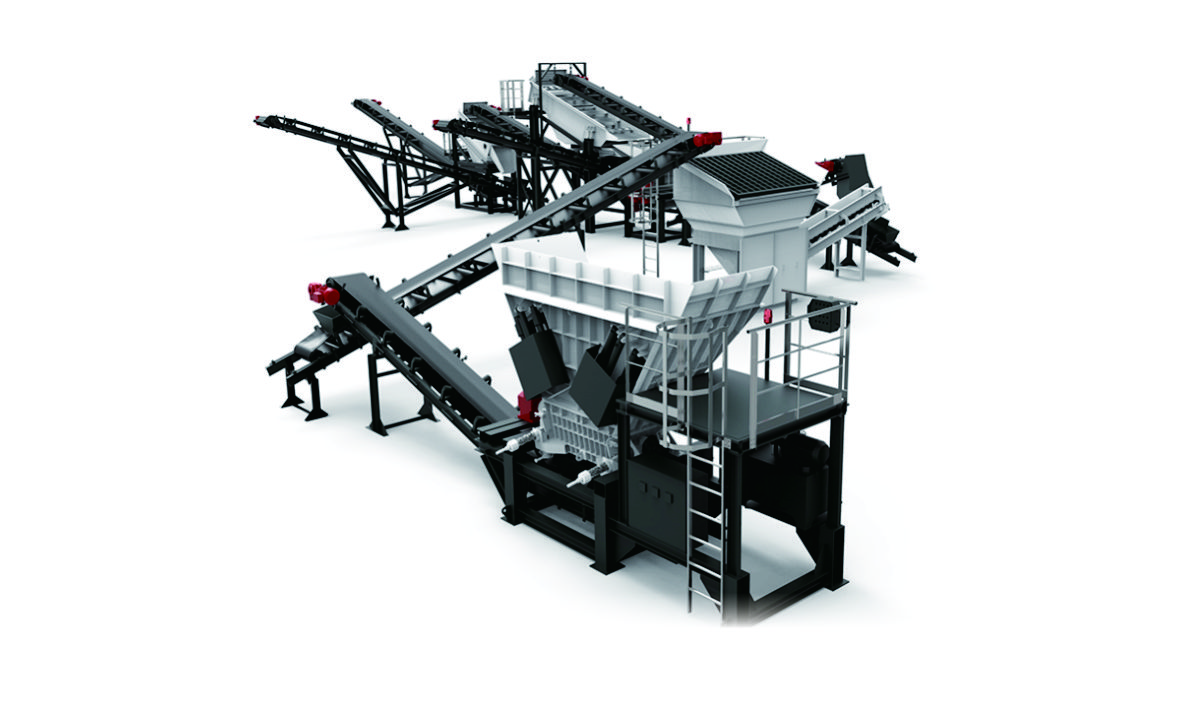

The crushing and screening system is a technology that breaks down bulk materials into smaller particles while separating out non-compliant granules through screening. These two processes interact synergistically: crushing generates finer particles, while screening filters and segregates those that fail to meet specifications.

The primary objective of chemical refining is to remove impurities and contaminants from materials, which necessitates physical treatment. This typically involves processes such as grinding, screening, centrifugation, and volatilization. During grinding, impurities are pulverized to increase surface area, thereby accelerating subsequent processing steps. Screening selectively removes oversized impurities, while centrifugation and volatilization separate solid or liquid contaminants from the raw material, resulting in purified products.

The primary functions of the pigging system include pipeline cleaning, product recycling, and equipment inspection and maintenance. By deploying movable plugs or pigs inside the pipeline, the system removes and recycles residual product in the inner wall of the pipeline, thereby ensuring pipeline cleanliness and efficient product recycling.

The filling and packaging system utilizes high-precision measuring devices and control systems to ensure each packaged unit meets predetermined quality and quantity standards. For instance, automatic quantitative filling machines employ measurement instruments such as electronic scale and flow meter to precisely control filling volumes, minimizing waste while guaranteeing product quality stability and consistency.

In material transfer, AGVs (Automated Guided Vehicles) and RGVs (Rail Guided Vehicles) are mainly used to improve efficiency, reduce costs and enhance operational flexibility.