The Z-Source Laboratory is an internationally first-class professional laboratory for the process industry, with its core mission focused on driving technological innovation and industrial upgrade within the sector. Leveraging state-of-the-art experimental equipment, advanced material handling technologies, and robust industry-academia-research collaboration resources, the laboratory has established a forward R&D framework encompassing "equipment-process-material-application".

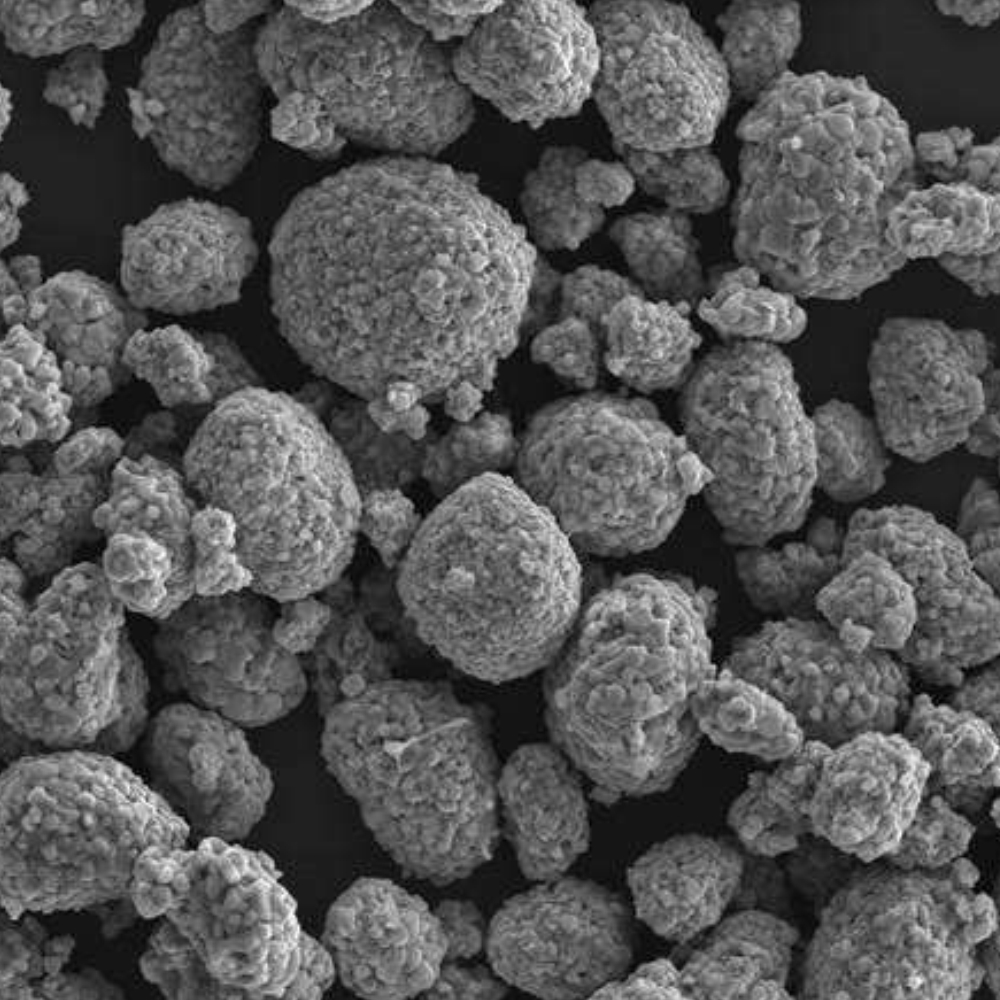

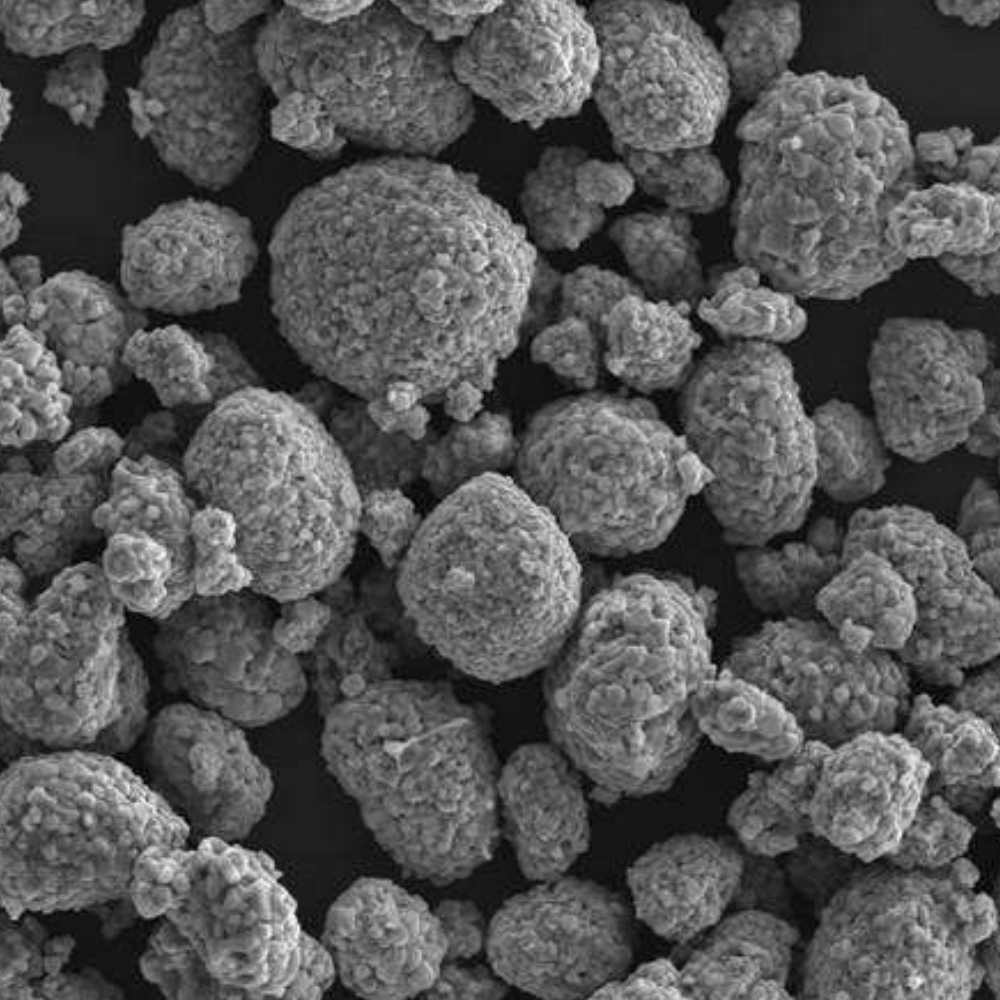

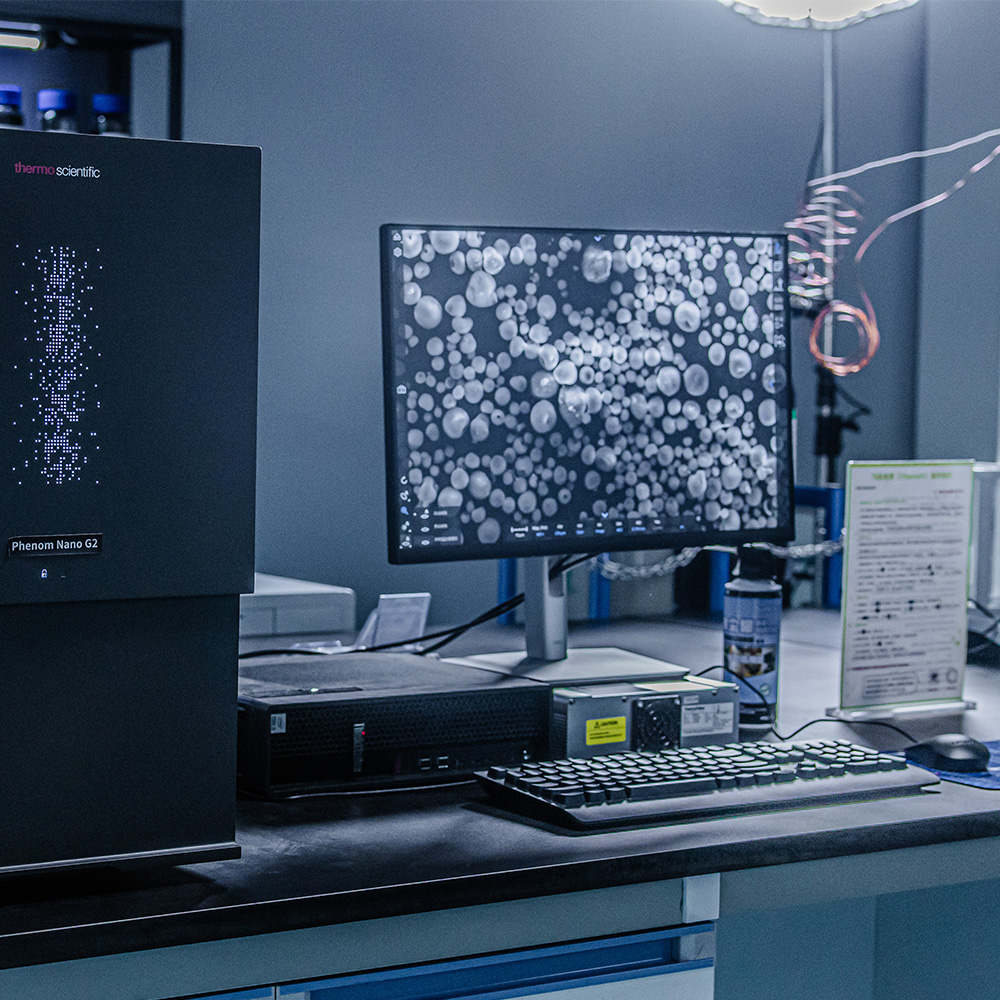

Testing material properties to enable forward development of corresponding process systems

For example: Cover material characteristic testing across dimensions from 2um to 100μm, including dynamic properties, physicochemical characteristics, etc.

Innovative Preparation Technology R&D: Focus on the efficiency and performance bottlenecks in material preparation, develop high-efficiency and low-carbon new processes, and break through the limitations of traditional technologies in terms of energy consumption and production capacity.

Phased R&D Transition: Establish a complete chain of "Experimental Exploration → Pilot-scale Verification → Industrialization Transition" to ensure the feasibility of new processes from the laboratory to the production line.

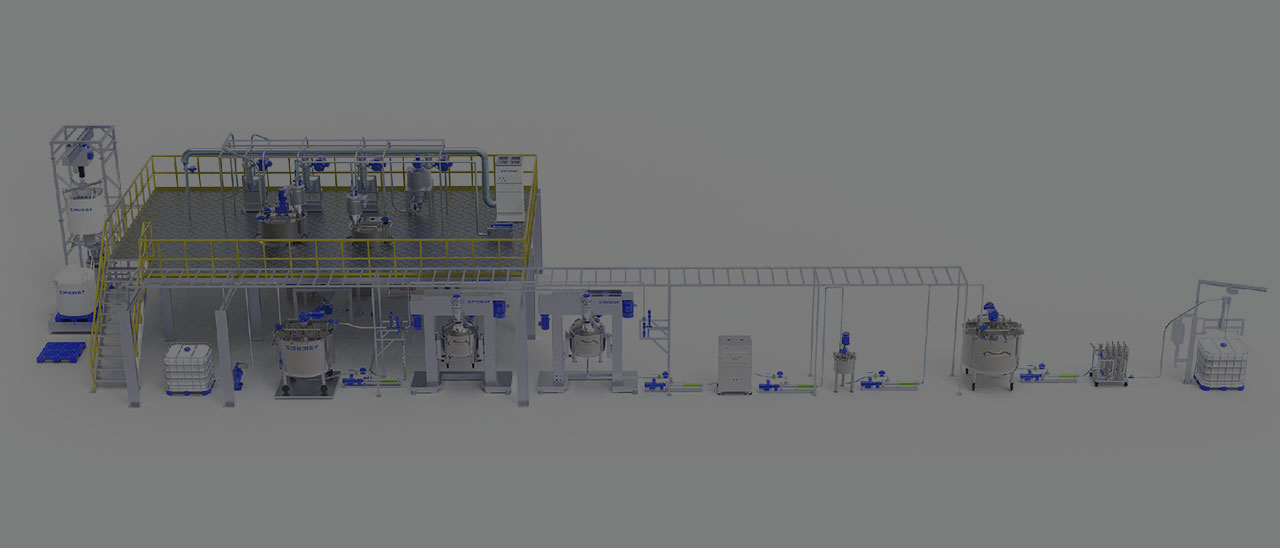

Flexible and efficient process design ability is needed to support the product development in the laboratory and the mass production of production line. While satisfying the process requirements, we help customers transform their existing production line, cooperate with them to complete the exploration and industrialization of advanced manufacturing process, and find the optimal solution from small pilots before deploying it to large-scale production.

In order to ensure process quality for the customers, the process design can be optimized by means of material process and vapor deposition technology, so as to shorten the process time and improve the overall productivity.

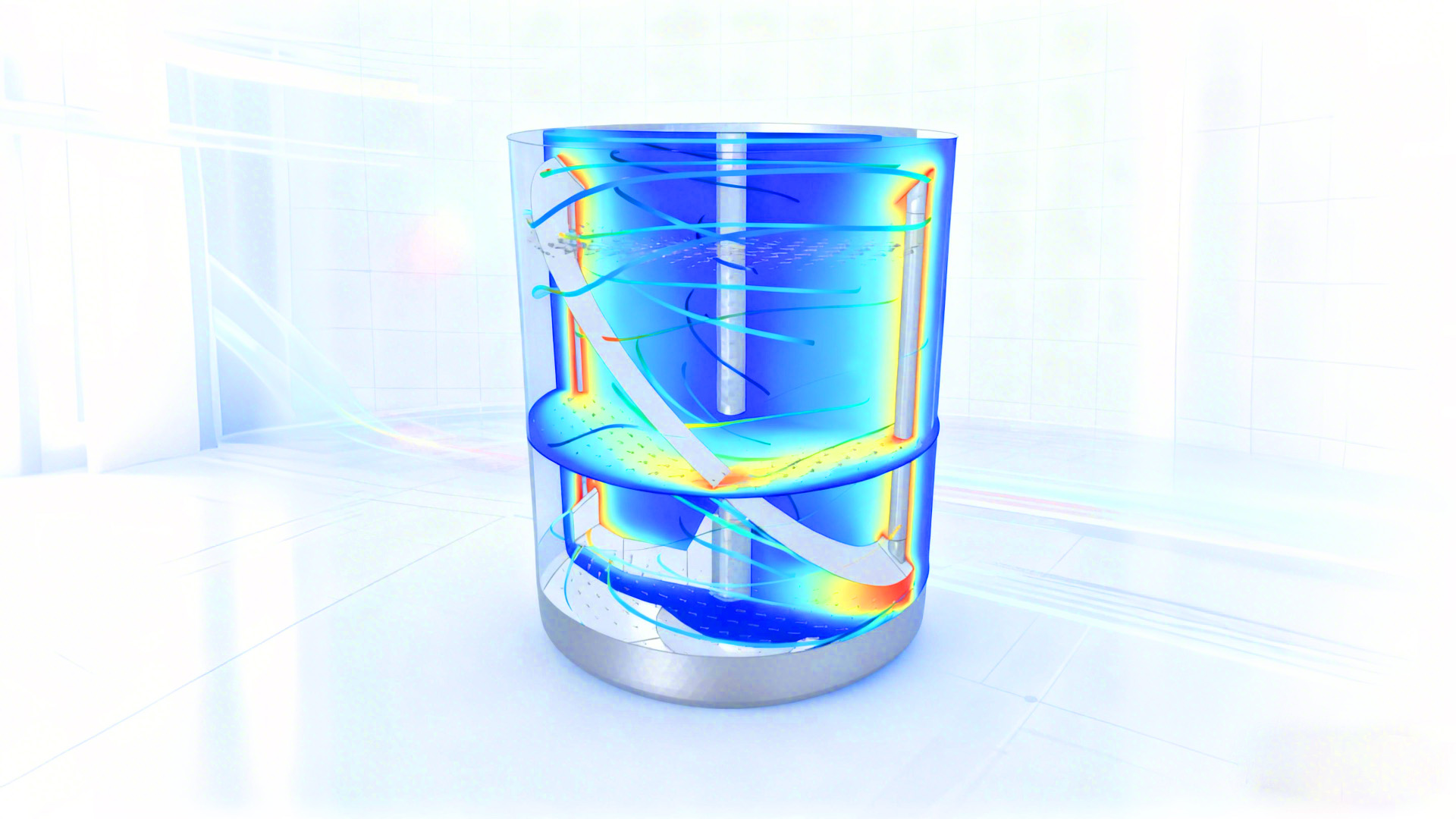

Digital Modeling of Bulk Materials: Utilizing CAE technology to construct simulation models with parameters that are highly consistent with actual industrial operating conditions, ensuring the reliability of simulation results.

Production Risk Prediction: Simulating bulk material behavior under extreme operating conditions to proactively identify potential risks such as blockage and uneven mixing, thereby providing preemptive safeguards for safe production.

Digital Twin Integration: Capable of interfacing with real-time data from the production line, providing core technological support for the construction of a digital twin for the bulk material handling system.

A specialized platform dedicated to the R&D and precise processing of micron- and nano-scale materials, focusing on breakthroughs in the localization of high-end materials technology and bridging the gap between "laboratory research and industrial application".