Pneumatic Conveying System

Process Overview:

The pneumatic conveying system is a technology that utilizes airflow energy to convey powdered or granular materials through enclosed pipelines, representing specific application of fluidization technology. It adopts specialized feeding devices to introduce materials into the pipeline at controlled rates and deliver materials to designated locations with positive or negative pressure gases (such as air, nitrogen or carbon dioxide). The system ensures all conveying equipment and instruments operate automatically, orderly and safely under centralized control.

Consult Now

Pneumatic conveying systems can be categorized into the following types:

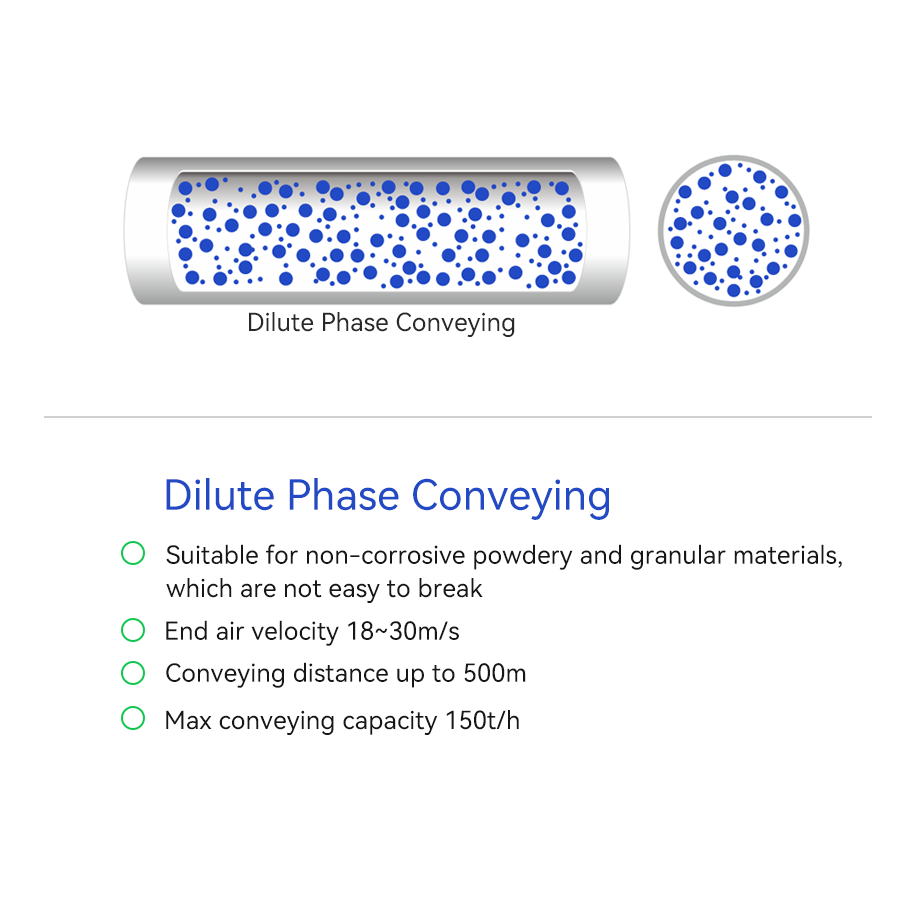

Dilute Phase Conveying

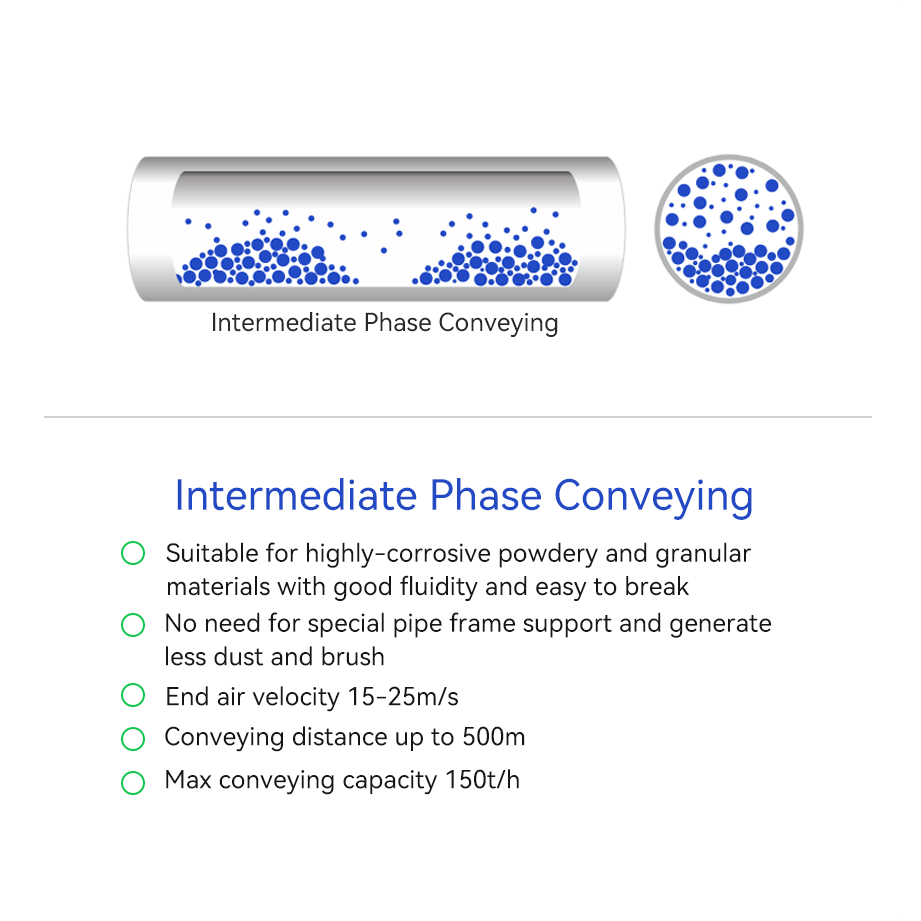

Intermediate Phase Conveying

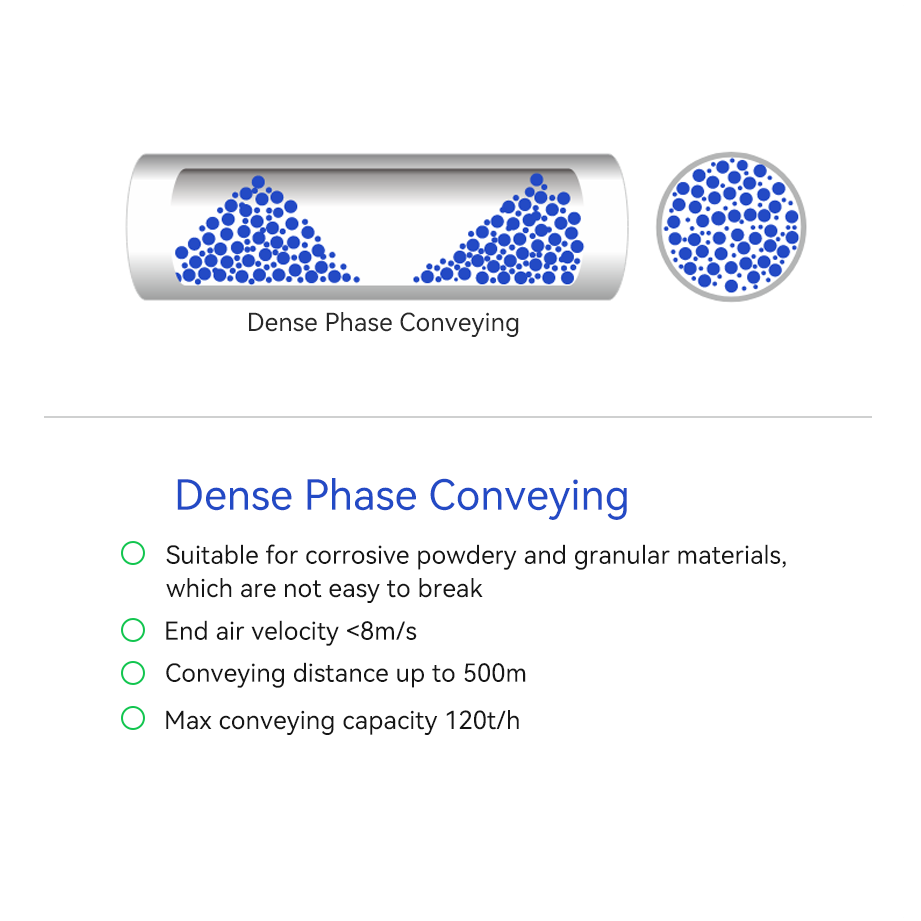

Dense Phase Conveying

Advantages

Closed system minimizes environmental pollution

High efficiency with compact footprint

Multi-functional and highly automated

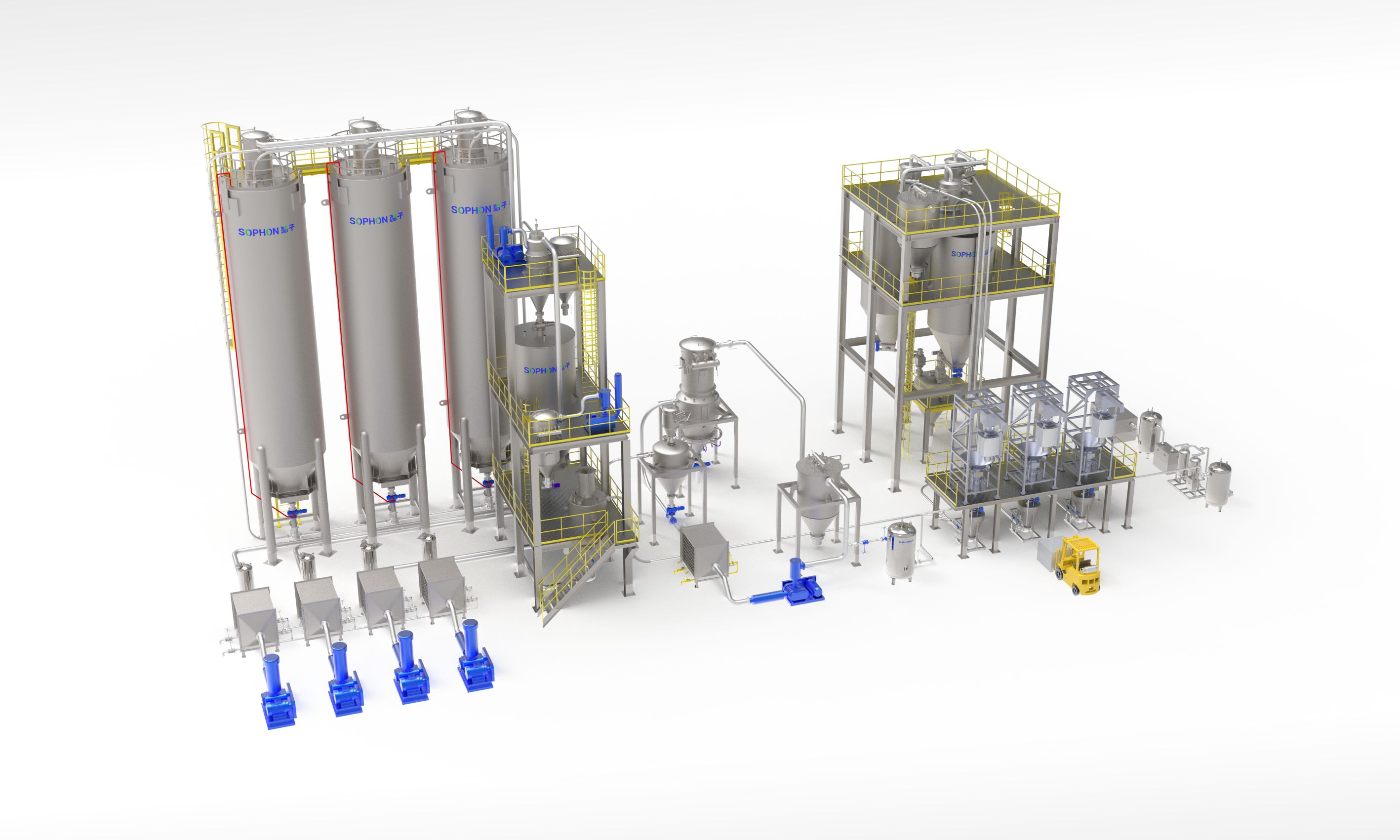

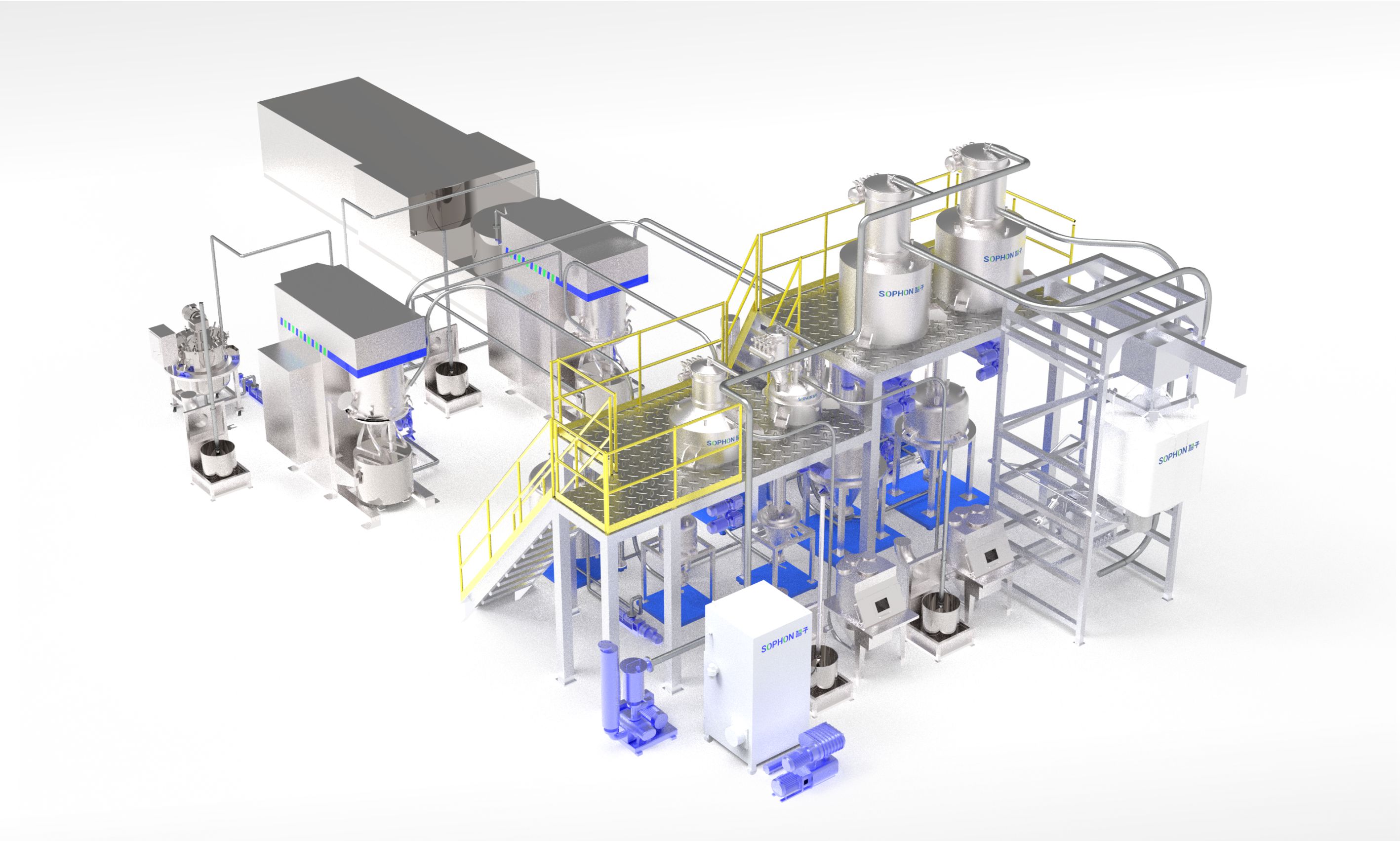

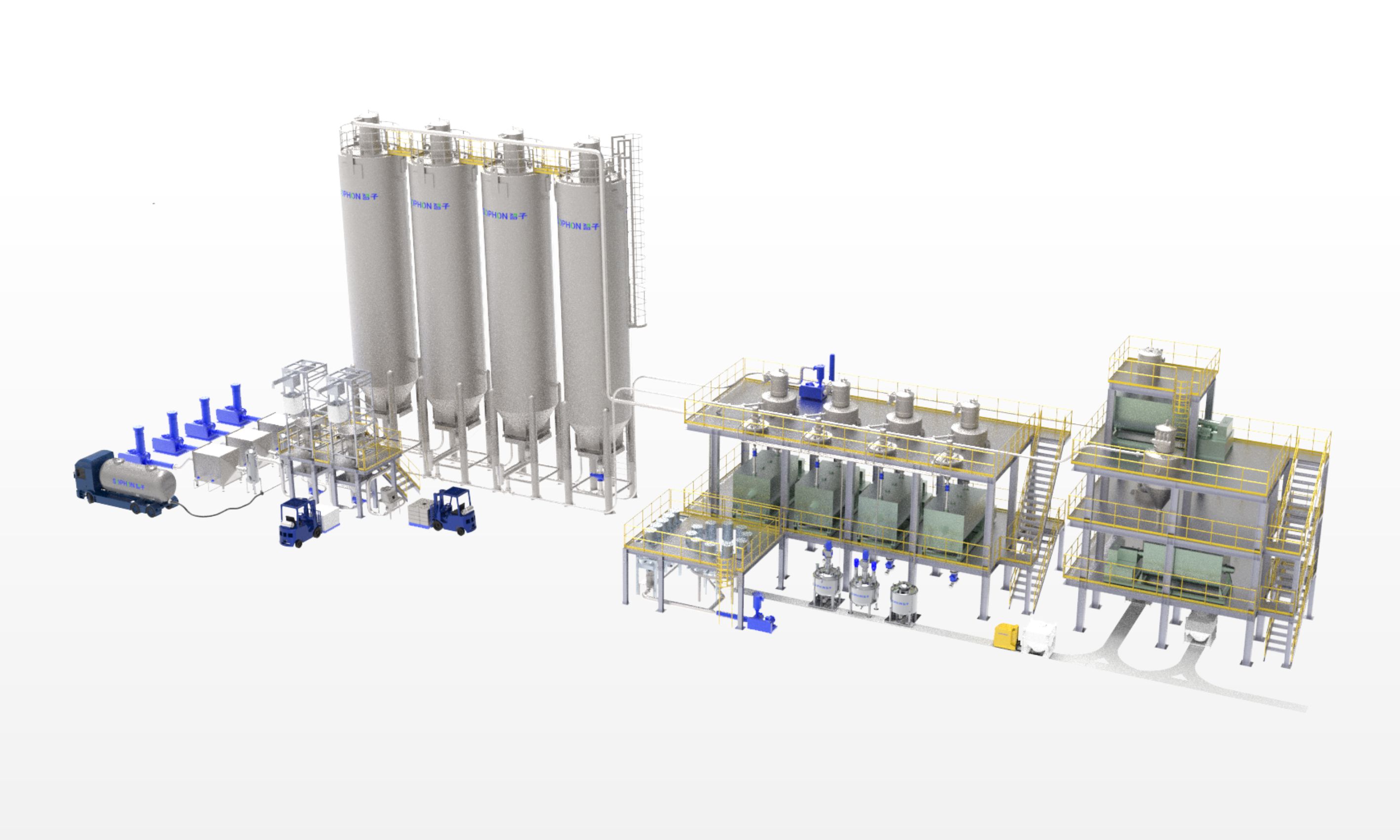

System 3D Diagram

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement