The rubber and plastics industry is a broad sector encompassing the production, processing and application of both rubber and plastic materials.

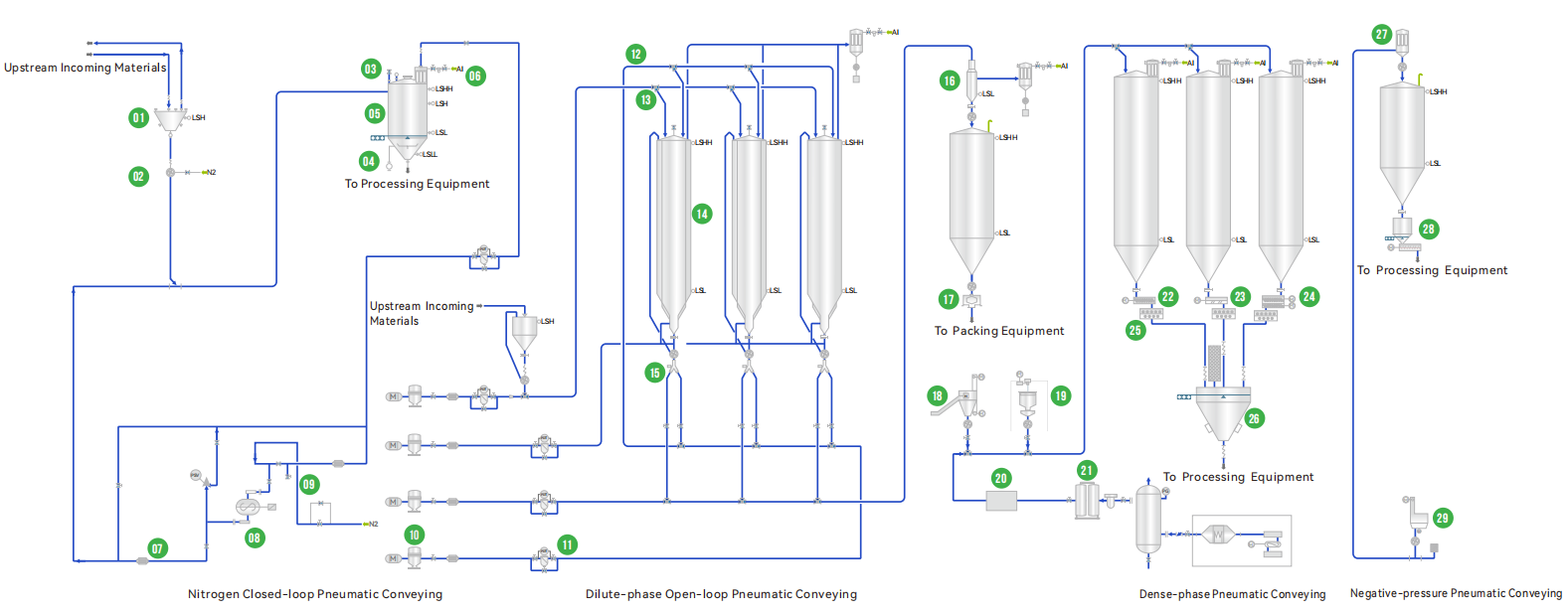

The plastic processing and preparation line is a production system that processes plastic raw materials into various plastic products, and its process usually includes raw material preparation, plasticization, molding, cooling, post-treatment and other sections.

Different plastic processing techniques and product types require distinct production lines and process flows. For example, extrusion production lines are used to produce plastic pipes, sheets and profiles. The plastified polymers are continuously extruded through precision dies to form specified cross-sectional geometries. As for blow molding production lines, they are mainly applied to manufacture hollow plastic containers (such as bottles and drums). The heated plastic parisons are placed into molds, expand to conform to mold cavities by compressed air and solidify to be hollow structures after cooling.