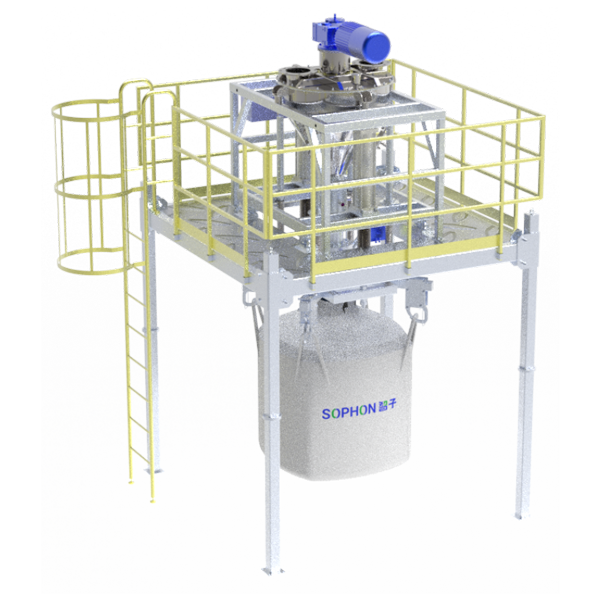

Vertical Bulk Bag Loader

By integrating automation technology, vacuum degassing system, and high-precision control, safe and efficient packaging of powder and granular materials is achieved.

Consult Now

Working Principles

Product Advantages

Applicable Fields

Applicable Materials

Powder Materials

Granular Materials

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement