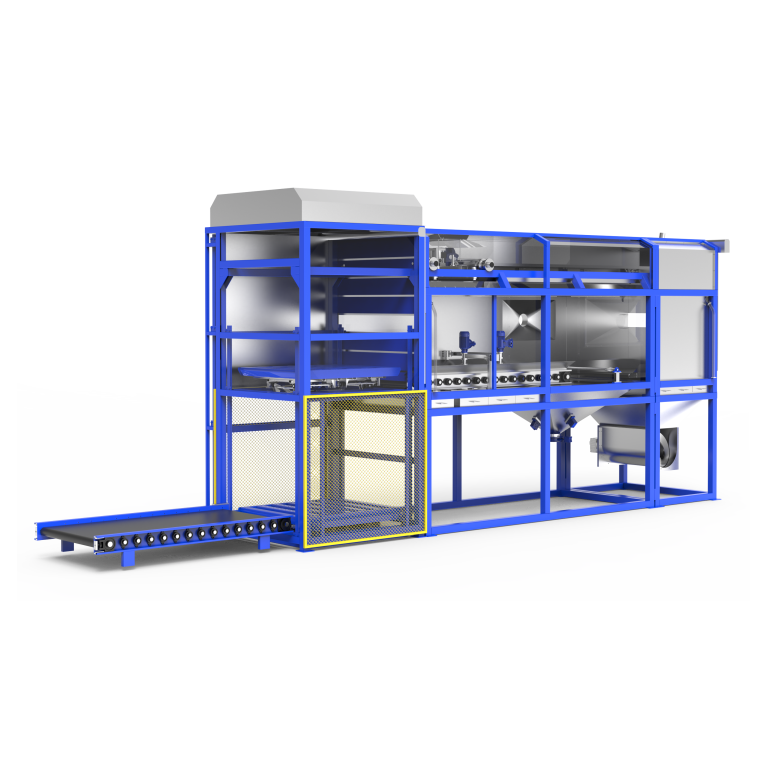

Fully-Automatic Bulk Bag Unloader

The Fully-Automatic Bulk Bag Unloader, specifically designed for the unpacking of bulk granular and powdered materials in industries such as chemical, new energy, minerals, and grain. lt effectively addresses issues associated with traditional manual unpacking, including low efficiency, heavy dust pollution, and significant material loss.

Consult Now

Product Introduction

The fully-automatic bulk bag unloader comprises the following parts: front-end conveying unit, lifting unit, bag breaking unit, discharging unit, dust removal system, waste bag collection unit, and control system.

Product Advantages

Applicable Fields

Applicable Materials

Powder Materials

Granular Materials

Blocky Materials

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement