The customer is a leading domestic and international automotive supplies enterprise, a publicly listed company, mainly engaged in the production and operation of silicone sealants, glass adhesives, high-end engine oils, coolants, antifreeze, and glass protection products.

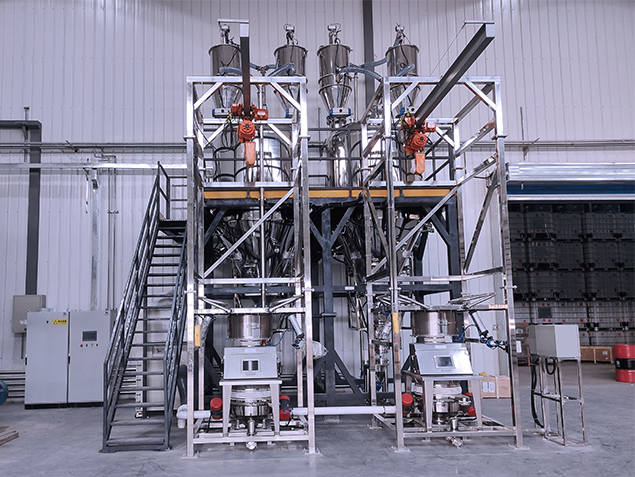

In March 2021, the customer signed a contract with our company for a automated production line of silicone sealant. Four production bases have been established in Shanghai, Foshan, Changchun, and Qingdao. The project consists of two main parts: a Powder Conveying and Metering System and an Adhesive Mixing and Automatic Feeding System.

The powder materials primarily include silicon dioxide, heavy calcium carbonate, mica, and calcium oxide. The liquid materials mainly comprise silicone oil and resin.

The key process involves feeding of powder materials via a integrated small/big bag unpacking machine, conveying them via vacuum conveying to the metering tank, and then transferring them from the metering tank to the kneader for mixing. The accuracy control requirement is 0.1%.

The liquid materials are transferred from IBC totes to a buffer tank via pumping, and then conveyed from the buffer tank to the kneader.

Our company provides comprehensive full-process services for the project, covering solution design, experimental testing, equipment development, production and delivery, installation and commissioning, and after-sales maintenance.

During the material characteristic experiments, in order to address the issues of false agglomeration of heavy calcium powder and the floating of silicon dioxide during the conveying process, our company adopted the patented vacuum-intermittent-circulating conveying method. Through multiple tests, we successfully resolved the problems related to conveying and metering accuracy. This approach also significantly reduced manual intervention, creating greater value for the customer.

Latest Recommendations

Latest Recommendations