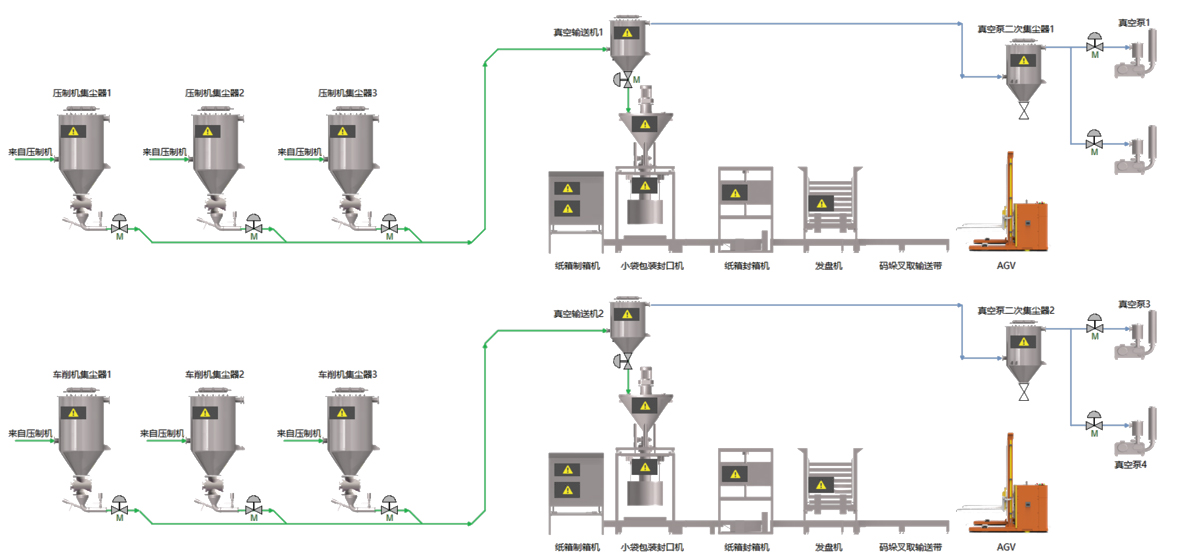

The customer is a benchmark enterprise in Inner Mongolia Autonomous Region in China and one of the five major state-owned enterprises, specializing in the research, development, and production of nuclear fuel elements. Faced with the challenges of graphite dust being lightweight, prone to dispersion, and difficult to collect effectively, traditional dust treatment methods struggled to achieve ideal dust collection results. In response to the specific needs of the customer's pressing dust workshop and turning dust workshop, SOPHON designed and implemented a centralized graphite dust treatment system. This system utilizes advanced equipment such as pneumatic butterfly valves, Roots blowers, and vacuum feeders, integrated with a precise automated control system, ensuring continuous and stable conveyance of graphite dust and significantly enhancing production efficiency.

Building on this foundation, SOPHON further introduced an intelligent monitoring and early warning system. This system utilizes big data analytics and machine learning technology to monitor equipment operating status in real time, enabling accurate prediction and advance warning of potential safety risks.

The customer has provided highly positive feedback on the centralized graphite dust treatment system supplied by SOPHON. They recognize that the system has not only resolved the long-standing dust treatment challenges but also significantly enhanced production efficiency and safety.

Latest Recommendations

Latest Recommendations