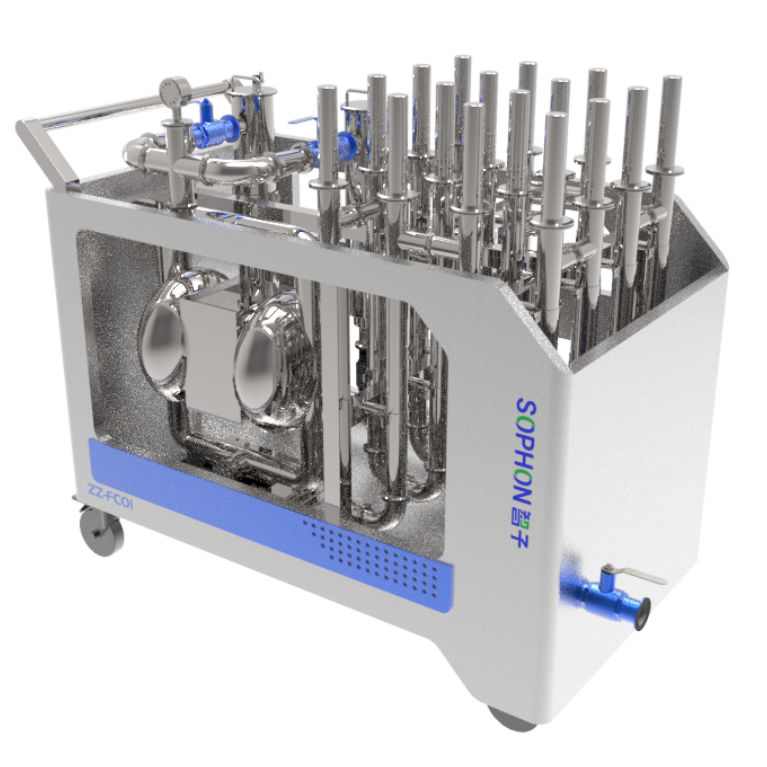

Iron Removal Filter Trolley

The Iron Removal Filter Trolley is a portable iron removal device specially designed for extracting magnetic particles from fluid or semi-fluid materials.

The fundamental working principle of the iron removal filter trolley is based on the magnetic adsorption of the magnetic rods, encompassing two stages: slurry magnetic separation and the cleaning of adsorbed magnetic substances. 1. Slurry Magnetic Separation Power Conveying: The pneumatic diaphragm pump, driven by 0.4-0.7 MPa compressed air, draws the material containing magnetic particles into the system. This avoids material alteration caused by the shear force of mechanical pumps. Gradient Filtration: The material first passes through a precision stainless steel filter, which intercepts large particles to prevent clogging on the magnetic rod surfaces, thereby enhancing subsequent magnetic adsorption efficiency. Deep Magnetic Removal: Magnetic particles are adsorbed onto the surface of the sleeve under the action of the Lorentz force. 2. Magnetic Substance Cleaning When the adsorbed magnetic impurities on the rods reach a certain level, manual cleaning is required: Quick Maintenance: After shutdown, remove the filter element and magnetic rods. Clean them thoroughly before reinstalling and resetting.