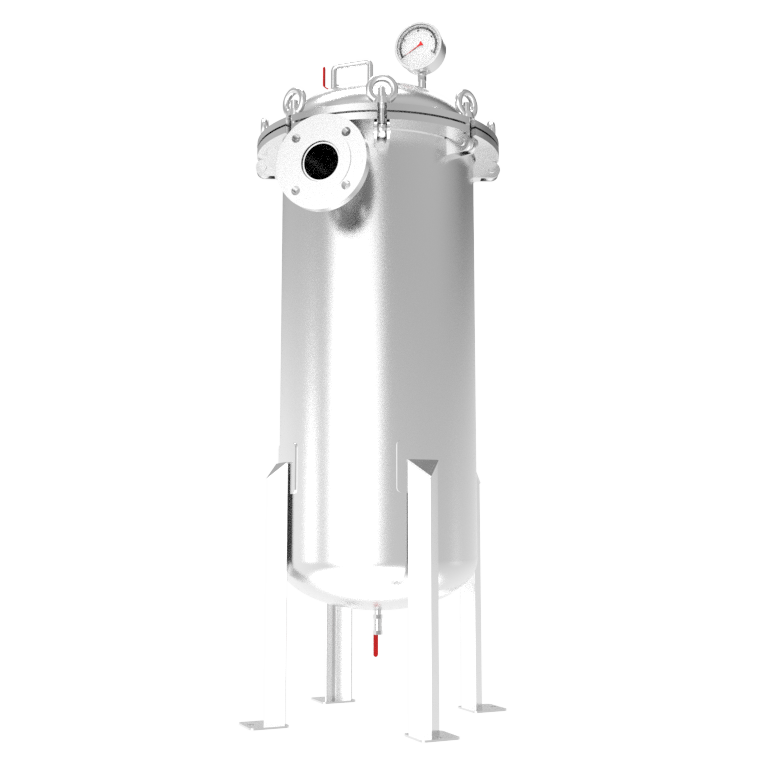

Bag Filter

The Bag Filter is a kind of efficient solid-liquid separation equipment that utilizes high-quality filter bags to capture impurity particles in fluids, achieving precise filtration. Featuring a compact structure, excellent sealing performance, simple operation, and convenient maintenance, it allows flexible replacement of filter bags with various precision levels according to filtration requirements. Combining reliability with practicality, it serves as key equipment for fluid purification in industrial production.

The filter employs a self-cleaning wedge-wire screen. Raw material enters the filter through the inlet and is filtered via the screen. Three scrapers on the outer wall of the screen scrape off larger particles adhering to the surface, which are then returned through the recycle pipe for reprocessing. Fine particles passing through the screen are discharged from the outlet for further use.