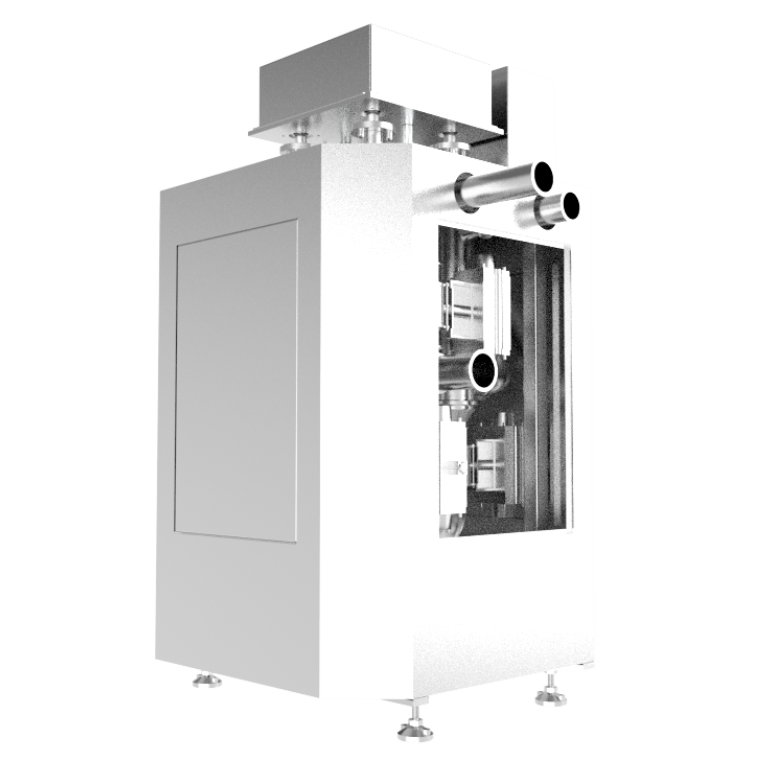

Magnetic Separator for High-viscosity Materials

The Magnetic Separator for High-viscosity Materials is specially designed to remove iron impurities and other ferromagnetic particles from fluid or semi-fluid materials with high viscosity.

1. Slurry Feeding: The raw slurry is transferred into the high-efficiency demagnetizer via a feeding system. 2. Magnetic Separation: As the slurry flows through the high-intensity magnetic zone, ferrous particles are absorbed and separated by the permanent magnetic rods. 3. Purified Slurry Discharge: The slurry after magnetic separation exits through the outlet and proceeds to downstream processes. 4. Automatic Slurry Drainage: The system automatically drains residual slurry from the separation chamber prior to cleaning. 5. Magnetic Particles Scraping: The magnetic rods are smoothly elevated via cylinder control. Scraping rings (fit tightly to the magnetic rod surface) remove adhered ferrous particles into the chamber. 6. Chamber Rinsing: Complete the rinsing of the chamber with detergent or high-pressure water, eliminating all residual contaminants. 7. Chamber Drying: Compressed air purging eliminates residual moisture/cleaning agent.