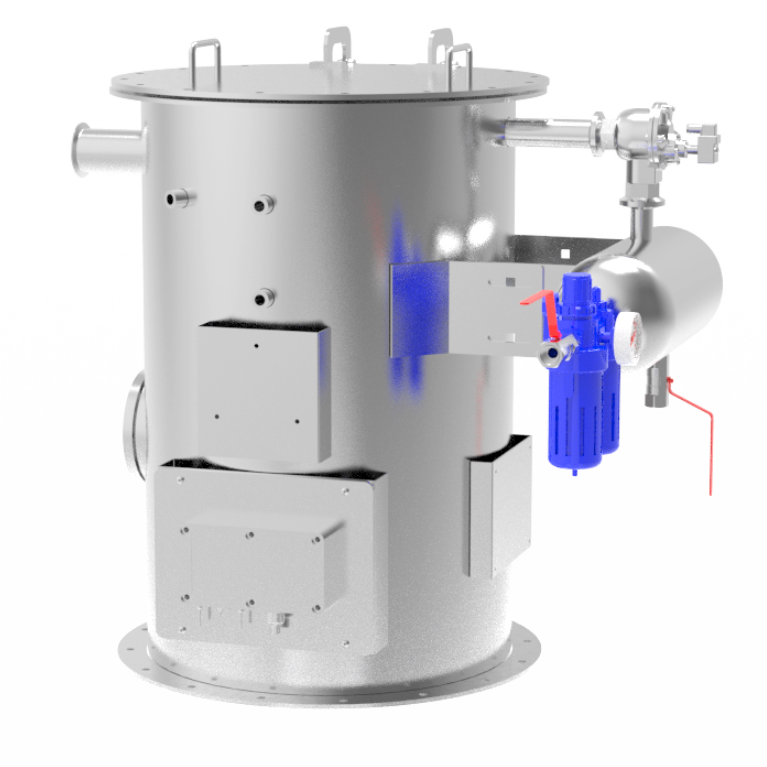

Dust Collector

The Dust Collector is a kind of professional equipment dedicated to collecting and removing dust, particles, and pollutants from gases. Through modular design and smart technology, it meets the demands of environmental protection, safety, and high efficiency in industrial production.

The dust-laden gas enters the lower receiving silo below the dust collector via pipeline. Oversized powders settle naturally to the bottom of the silo due to reduced flow velocity and gravity. The gas, after preliminary sedimentation, rises into the filter bag/cartridge zone, where fine dust particles are captured. Clean gas is then discharged from the dust collector, achieving gas-dust separation. When the dust on the filter bag/cartridge accumulates to a certain level, the pulse cleaning system is activated. High-pressure gas is injected instantaneously, causing the adhering dust to dislodge and fall back into the receiving silo.