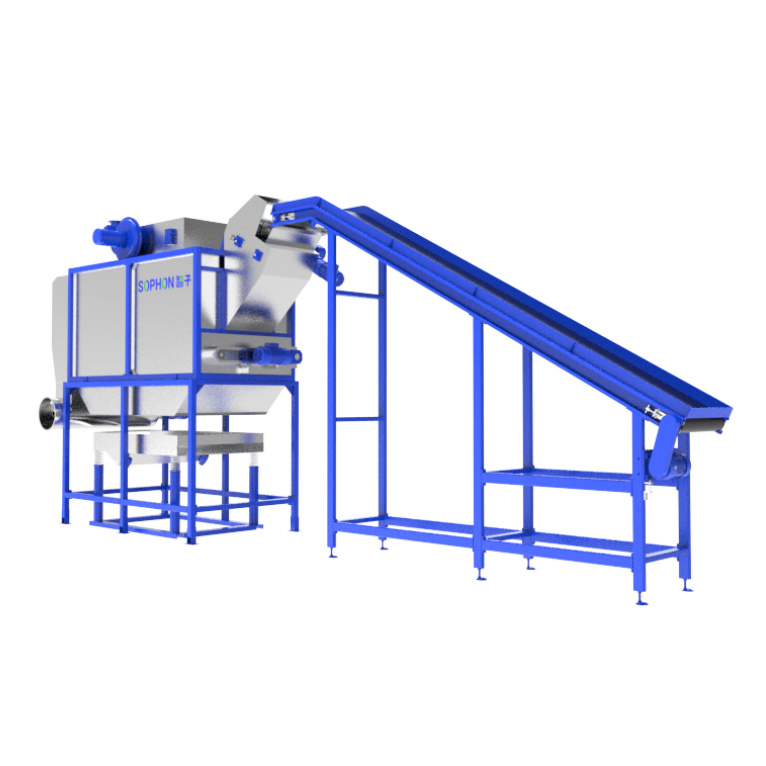

Fully-Automatic Small Bag Unpacking Machine

The Fully-Automatic Small Bag Unpacking Machine (compatible with bags ≤25kg) is specifically designed for unpacking granular and powder materials in industries such as chemicals, new energy, food, and pharmaceuticals. It effectively addresses issues associated with traditional manual unpacking, including low efficiency, high labor intensity, and susceptibility to material contamination.

The fully-automatic small bag unpacking machine is a kind of equipment that completes the unpacking of bagged materials through an automated process. The working principle is as follows: a conveyor belt transports the bags to the unpacking station, where blades or cutting devices precisely slit the bag. The material inside is then unloaded via vibrating conveyance or negative pressure adsorption, while a dust removal device filters airborne particles to prevent contamination. Finally, empty bags are automatically separated and collected. The entire process requires no manual intervention in unpacking and unloading, achieving efficient, clean, and automated operation.