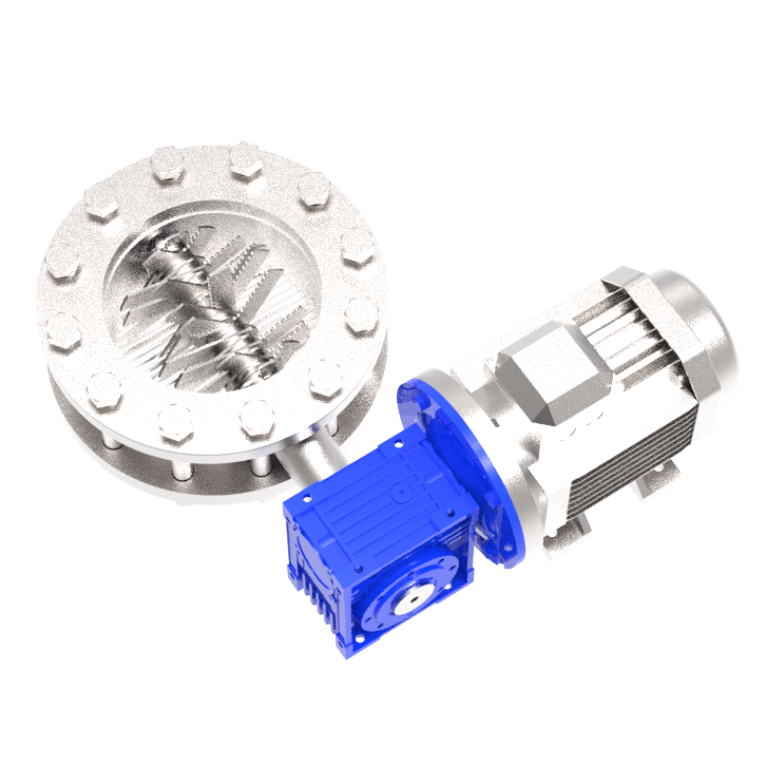

Pipeline Crusher

The Pipeline Crusher is a highly efficient pre-processing device for industrial materials, primarily used to break down compacted materials. It adopts mechanical shearing and impact forces to crush medium- to low-hardness materials into a uniform particle size, such as blocky and agglomerated materials. This effectively resolves pipeline clogging issues and ensures the stable operation of downstream equipment.

Consult Now

Working Principles

The pipeline crusher utilizes a low-speed and high-torque power system to achieve efficient crushing of materials within the pipeline through the pressing and shearing action between its blades and the screen mesh.

Product Advantages

产品优势

Applicable Materials

Powder Materials

Granular Materials

Blocky Materials

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement