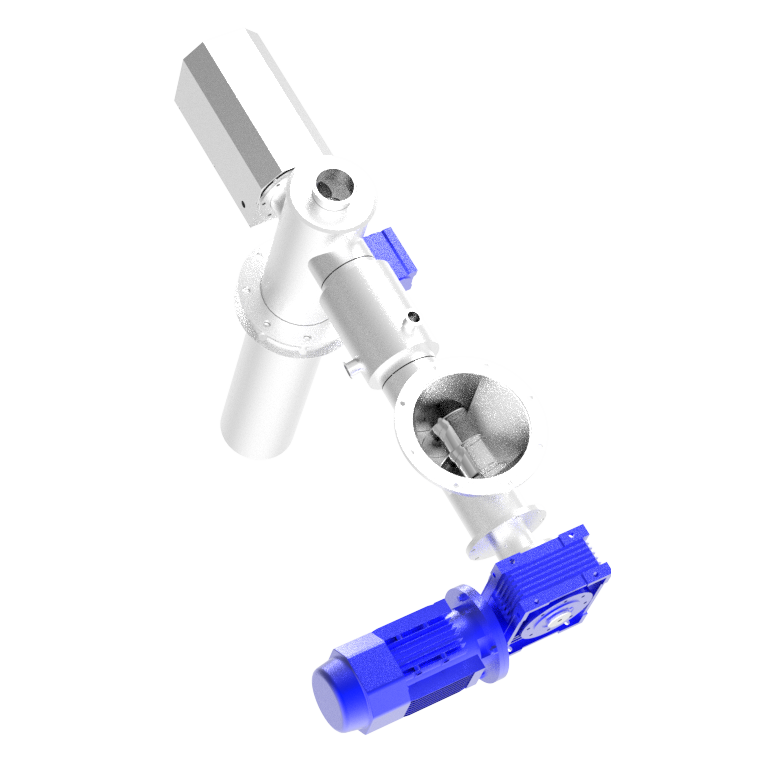

Screw Conveyor

The screw conveyor (auger) is a core machine for industrial material conveying, specifically designed for the continuous and enclosed conveyance of powder, granular, and blocky materials.

Consult Now

Working Principles

The motor drives the screw flights to rotate, while the blades propel materials axially through frictional thrust.

Product Advantages

Product Advantages

Applicable Materials

Powder Materials

Granular Materials

Blocky Materials

Liquid Materials

Slurries

We look forward to your message

Fill in the information in the form, and we will provide you with more accurate recommendation information.

I understand and agree to use and transfer my personal information in accordance with the privacy statement