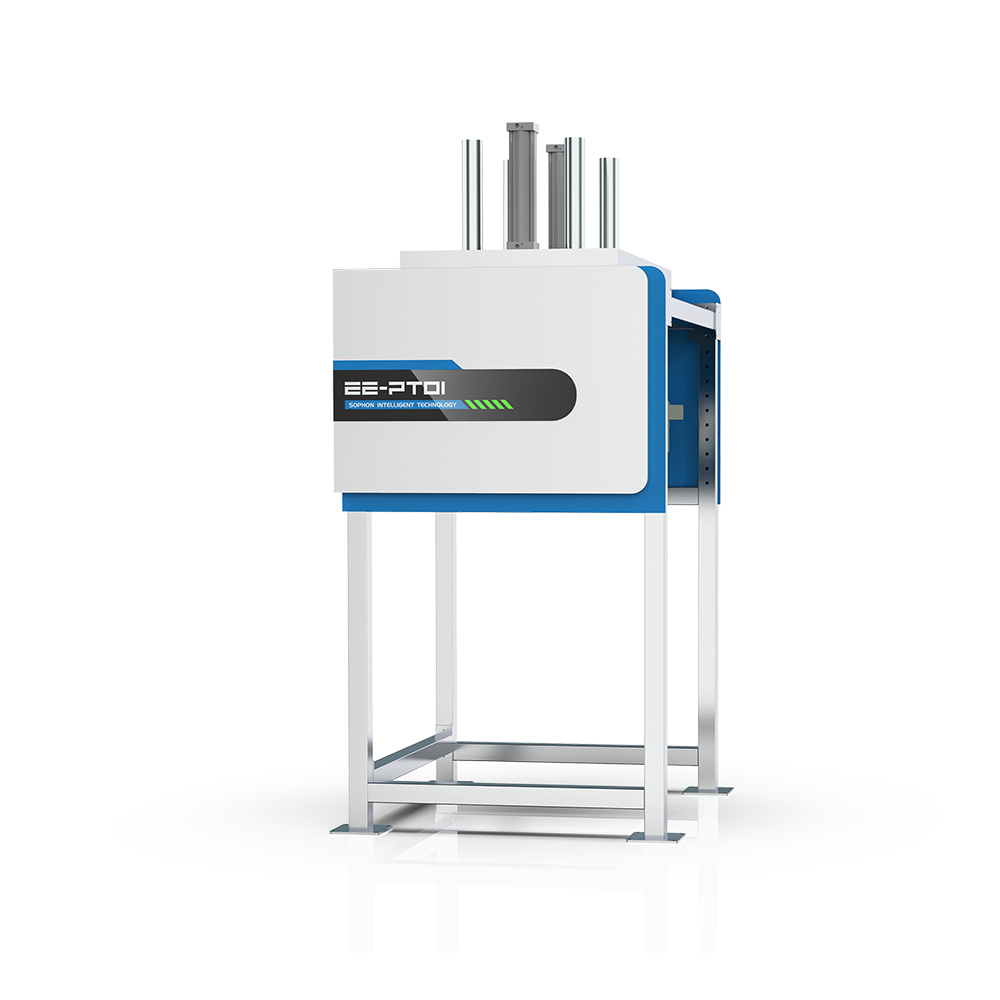

Pipeline Iron Remover

The Pipeline Iron Remover is a magnetic filtration device based on permanent magnet technology, specifically designed to remove ferromagnetic impurities from liquids, slurries, or semi‑fluid materials.

The core working principle of the pipeline iron remover is based on the magnetic adsorption of the magnetic rods, which includes two stages: slurry magnetic separation and magnetic substance cleaning. Slurry Magnetic Separation: When fluid containing impurities flows through the iron remover, the high-gradient magnetic field exerts a Lorentz force on ferromagnetic particles, causing them to deviate from the original flow path and be adsorbed onto the surface of the stainless steel sleeve, while clean material continues to be conveyed to the next process. Magnetic Substance Cleaning: When the magnetic impurities adsorbed on the magnetic rods reach a certain level, manual cleaning is required, which can be divided into standard cleaning and easy cleaning.