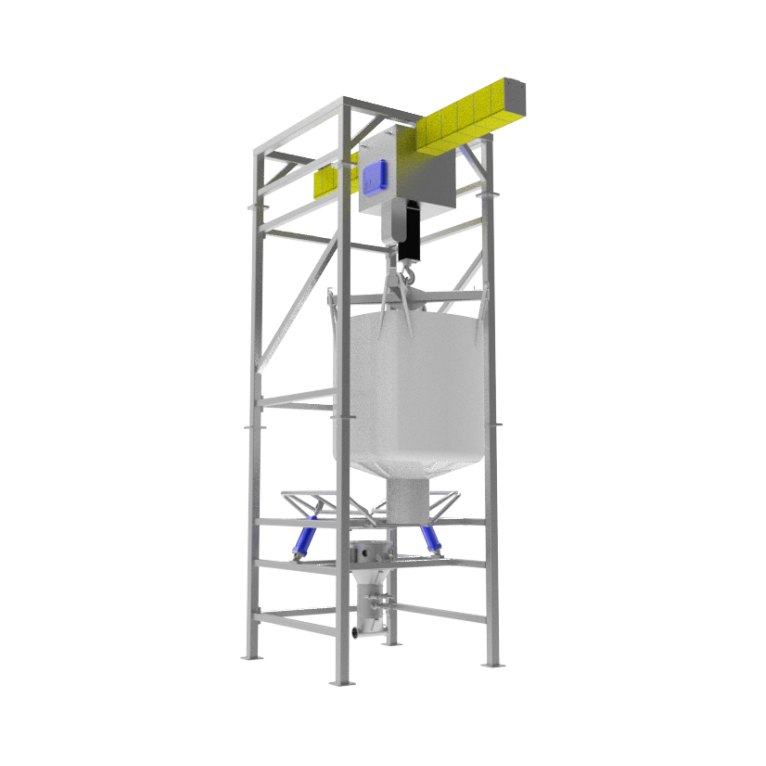

Bulk Bag Unloader

The bulk bag unloader (emptying station/ feeding station of bulk bags) is an automated equipment designed for efficient, safe, and dust-free unpacking of big bags containing 200-2000kg materials. Compared with the equipment, traditional manual unpacking features low efficiency, dust pollution, and safety hazards.

The bulk bag is hoisted and secured onto the support frame via a lifting device. After the bag spout is opened or the bag is cut, the material falls into the equipment by gravity. It is then processed by an anti-bridging device to prevent agglomeration and a screening device to remove impurities, before being conveyed to downstream equipment via a screw or pneumatic conveyor. Simultaneously, a negative-pressure dust collection system captures airborne dust to prevent dispersion, enabling efficient and dust-free unloading of bulk bag materials.