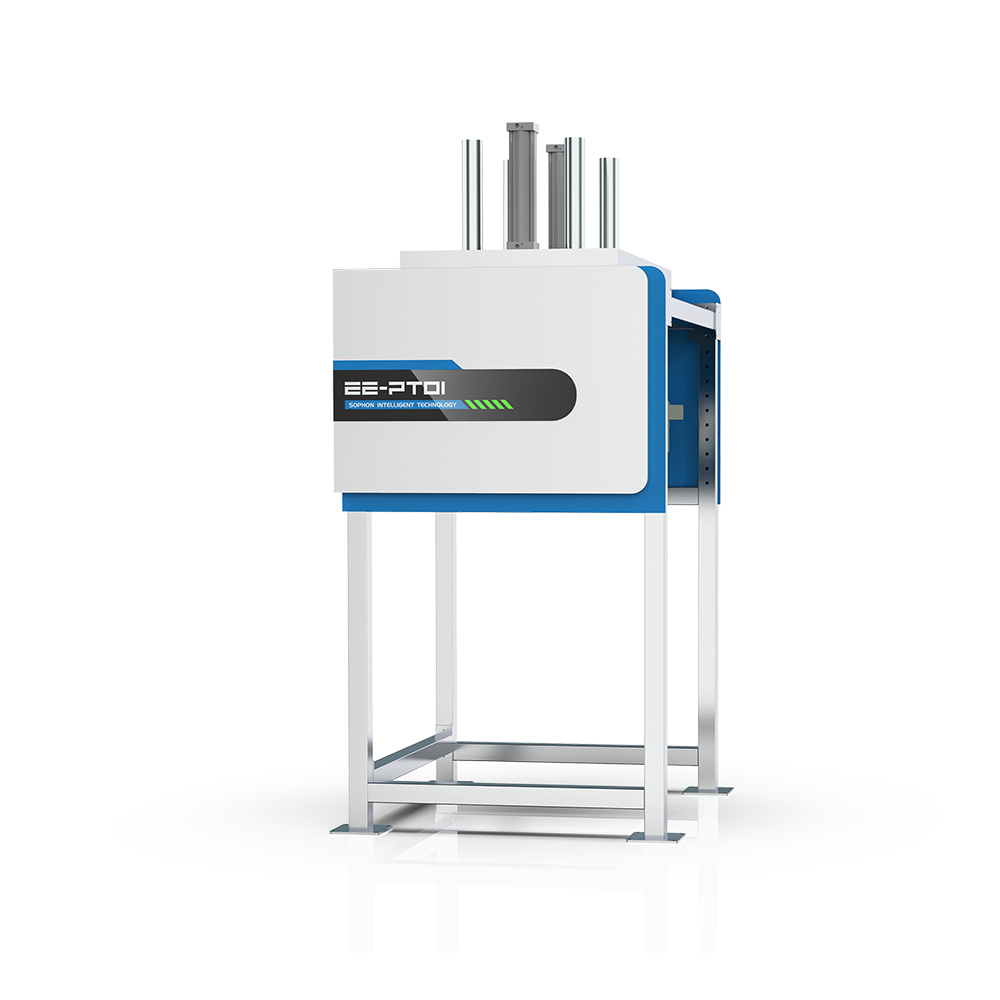

Scraper Filter

The Scraper Filter is an automatic, self-cleaning, and high-efficiency filtration machine. Its core mechanism involves a built-in scraper and screen working in tandem to continuously remove retained impurities from the filter screen. The equipment completes self-cleaning without the need for shutdown, enabling continuous filtration and eliminating frequent disassembly, cleaning, or replacement of filter media. It is suitable for high-viscosity fluids containing particulate impurities, offering excellent temperature and pressure resistance. Widely used in industries such as chemical, petroleum, and water treatment, it effectively reduces labor costs and ensures uninterrupted production processes. This filter serves as an efficient solution for industrial fluid purification.

The scraper filter operates on the core principle of solid-liquid separation, utilizing the porous structure of the filter bag to achieve precise filtration. Under pressure, the fluid to be treated enters the filter chamber. As it passes through the filter bag of specified precision, suspended particles and impurities are retained by the bag, while the clean fluid exits through its pores. Filter bags with different pore sizes can be selected as needed, enabling graded filtration through physical interception. This ensures the fluid meets the purification requirements of the process. The equipment is straightforward, efficient, stable, and reliable.